Solid carbide drills offer superior performance due to their exceptional hardness and durability, making them ideal for high-speed machining applications. Unlike traditional drills, they maintain their sharpness for extended periods, leading to improved precision and consistency in drilling operations. These drills efficiently handle tough materials such as hardened steel and stainless steel, ensuring minimal tool wear and longer tool life. Their rigidity helps in achieving accurate hole dimensions, reducing the risk of deviations. However, solid carbide drills are less suited for soft materials, as their hardness may lead to chipping or tool breakage under certain conditions.

VIEW MORE SOLID CARBIDE DRILL BITS

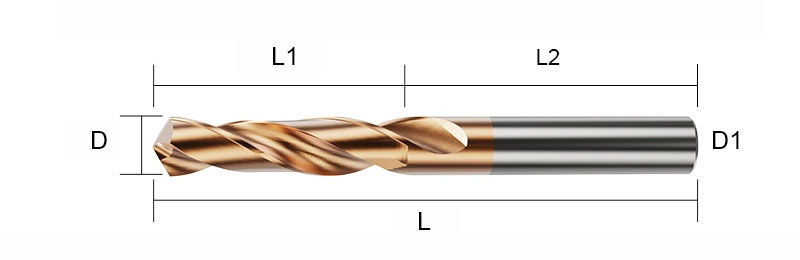

| Number of cutting edges Z: 2/3 |  |

| Coating: TiAlN | |

| Tool material: Solid carbide | |

| Point angle: 140 ° |

| D SPECIFICATION | D1 SHANK DIAMETER | L TOTAL LENGTH | L1 FLUTE LENGTH | L2 SHANK LENGTH |

| D3 - D3.7 | 6 | 62 | 20 | 36 |

| D3.8 - D4.7 | 6 | 66 | 24 | 36 |

| D4.8 - D6 | 6 | 66 | 28 | 36 |

| D6.1 - D7 | 8 | 79 | 34 | 36 |

| D7.1 - D8 | 8 | 79 | 41 | 36 |

| D8.1 - D10 | 10 | 89 | 47 | 40 |

| D10.3 - D12 | 12 | 102 | 55 | 45 |

| D12.1 - D14 | 14 | 107 | 60 | 45 |

| D14.1 - D16 | 16 | 115 | 65 | 45 |

| D16.1 - D18 | 18 | 123 | 73 | 50 |

| D18.1 - D20 | 20 | 131 | 79 | 50 |

| D SPECIFICATION | D1 SHANK DIAMETER | L TOTAL LENGTH | L1 FLUTE LENGTH | L2 SHANK LENGTH |

| D3 - D3.7 | 6 | 66 | 28 | 36 |

| D4 - D4.7 | 6 | 74 | 36 | 36 |

| D4.8 - D6 | 6 | 82 | 44 | 36 |

| D6.1 - D8 | 8 | 91 | 53 | 36 |

| D8.1 - D10 | 10 | 103 | 61 | 40 |

| D10.3 - D12 | 12 | 118 | 71 | 45 |

| D12.1 - D14 | 14 | 124 | 77 | 48 |

| D14.1 - D16 | 16 | 133 | 83 | 48 |

| D16.1 - D18 | 18 | 143 | 93 | 48 |

| D18.1 - D20 | 20 | 153 | 101 | 50 |

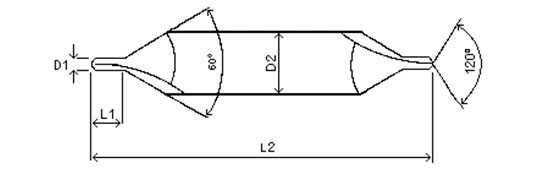

The main features of Center Drill Bits are that they create an initial guide hole, ensuring accuracy in subsequent drilling processes and preventing the drill from wandering. By forming a small, centered hole, they provide stability for larger drill bits, improving alignment and reducing the risk of misaligned holes. The resulting pilot holes are clean and precise, contributing to smoother drilling with minimal deflection. Center drill bits are commonly used in lathe operations and other precision machining tasks. However, they are less effective for deeper drilling or materials that do not require precise centering.

| Type of product: Centre drill |  |

| Tool material: HSS / Solid carbide | |

| Type: A / B / R | |

| Cutting direction: Left-hand / Right-hand |

| D1 Size | D2 Body Diameter | L2 Overall Length | D1 Size | D2 Body Diameter | L2 Overall Length | |

| 0.5 | 3.15 | 25 | 3.15 | 8 | 50 | |

| 0.8 | 3.15 | 25 | 4 | 10 | 56 | |

| 1 | 3.15 | 31.5 | 5 | 12.5 | 63 | |

| 1.25 | 3.15 | 31.5 | 6.3 | 16 | 71 | |

| 1.6 | 4 | 35.5 | 8 | 20 | 80 | |

| 2 | 5 | 40 | 10 | 25 | 100 | |

| 2.5 | 6.3 | 45 | 12.5 | 31.5 | 125 |

| D1 Size | D2 Body Diameter | L2 Overall Length | D1 Size | D2 Body Diameter | L2 Overall Length | |

| 0.5 | 3.15 | 25 | 3.15 | 8 | 50 | |

| 0.8 | 3.15 | 25 | 4 | 10 | 56 | |

| 1 | 3.15 | 31.5 | 5 | 12.5 | 63 | |

| 1.25 | 3.15 | 31.5 | 6.3 | 16 | 71 | |

| 1.6 | 4 | 35.5 | 8 | 20 | 80 | |

| 2 | 5 | 40 | 10 | 25 | 100 | |

| 2.5 | 6.3 | 45 | 12.5 | 31.5 | 125 |

| D1 Size | D2 Body Diameter | L2 Overall Length | D1 Size | D2 Body Diameter | L2 Overall Length | |

| 1 | 4 | 35.5 | 4 | 14 | 67 | |

| 1.25 | 5 | 40 | 5 | 16 | 75 | |

| 1.6 | 6.3 | 45 | 6.3 | 20 | 80 | |

| 2 | 8 | 50 | 8 | 25 | 100 | |

| 2.5 | 10 | 56 | 10 | 31.5 | 125 | |

| 3.15 | 11.2 | 60 |

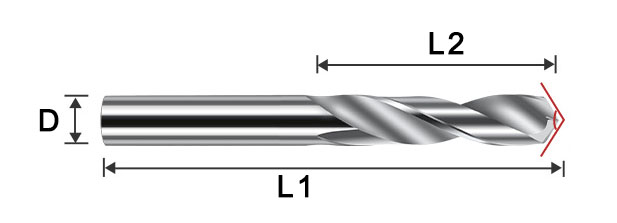

Twist Drill Bits are precision tools designed to create cylindrical holes through rotational cutting. Their helical flutes ensure efficient chip evacuation, reducing friction and heat buildup, which enhances hole accuracy and tool life. Available in various materials, each offers unique advantages. HSS (High-Speed Steel) bits are versatile and durable, suitable for general applications in wood, plastics, and mild steel. HSSE (HSS with cobalt) provides increased heat resistance and strength, ideal for harder materials like stainless steel. Solid carbide bits, known for their exceptional hardness and wear resistance, excel in high-speed, precision machining of hard materials but can be brittle under improper use. Material selection is critical for optimizing performance based on application.

| Tool material: HSS (High Speed Steel) |  |

| Standard: DIN338, DIN340, DIN1869, DIN1897 | |

| Point angle: 118 ° / 135 ° | |

| Cutting direction: Left-hand / right-hand |

| D | L1 | L2 | D | L1 | L2 | D | L1 | L2 | D | L1 | L2 | |||

| 0.2 | 19 | 2.5 | 2 | 49 | 24 | 6.2 | 101 | 63 | 11.4 | 142 | 94 | |||

| 0.22 | 19 | 2.5 | 2.05 | 49 | 24 | 6.3 | 101 | 63 | 11.5 | 142 | 94 | |||

| 0.25 | 19 | 3 | 2.1 | 49 | 24 | 6.4 | 101 | 63 | 11.6 | 142 | 94 | |||

| 0.28 | 19 | 3 | 2.15 | 53 | 27 | 6.5 | 101 | 63 | 11.7 | 142 | 94 | |||

| 0.3 | 19 | 3 | 2.2 | 53 | 27 | 6.6 | 101 | 63 | 11.8 | 142 | 94 | |||

| 0.32 | 19 | 4 | 2.25 | 53 | 27 | 6.7 | 101 | 63 | 11.9 | 151 | 101 | |||

| 0.35 | 19 | 4 | 2.3 | 53 | 27 | 6.8 | 109 | 69 | 12 | 151 | 101 | |||

| 0.38 | 19 | 4 | 2.35 | 53 | 27 | 6.9 | 109 | 69 | 12.1 | 151 | 101 | |||

| 0.4 | 20 | 5 | 2.4 | 57 | 30 | 7 | 109 | 69 | 12.2 | 151 | 101 | |||

| 0.42 | 20 | 5 | 2.45 | 57 | 30 | 7.1 | 109 | 69 | 12.3 | 151 | 101 | |||

| 0.45 | 20 | 5 | 2.5 | 57 | 30 | 7.2 | 109 | 69 | 12.4 | 151 | 101 | |||

| 0.48 | 20 | 5 | 2.55 | 57 | 30 | 7.3 | 109 | 69 | 12.5 | 151 | 101 | |||

| 0.5 | 22 | 6 | 2.6 | 57 | 30 | 7.4 | 109 | 69 | 12.6 | 151 | 101 | |||

| 0.52 | 22 | 6 | 2.65 | 57 | 30 | 7.5 | 109 | 69 | 12.7 | 151 | 101 | |||

| 0.55 | 24 | 7 | 2.7 | 61 | 33 | 7.6 | 117 | 75 | 12.8 | 151 | 101 | |||

| 0.58 | 24 | 7 | 2.75 | 61 | 33 | 7.7 | 117 | 75 | 12.9 | 151 | 101 | |||

| 0.6 | 24 | 7 | 2.8 | 61 | 33 | 7.8 | 117 | 75 | 13 | 151 | 101 | |||

| 0.62 | 26 | 8 | 2.85 | 61 | 33 | 7.9 | 117 | 75 | 13.1 | 151 | 101 | |||

| 0.65 | 26 | 8 | 2.9 | 61 | 33 | 8 | 117 | 75 | 13.2 | 151 | 101 | |||

| 0.68 | 26 | 8 | 2.95 | 61 | 33 | 8.1 | 117 | 75 | 13.3 | 160 | 108 | |||

| 0.7 | 28 | 9 | 3 | 61 | 33 | 8.2 | 117 | 75 | 13.4 | 160 | 108 | |||

| 0.72 | 28 | 9 | 3.1 | 65 | 36 | 8.3 | 117 | 75 | 13.5 | 160 | 108 | |||

| 0.75 | 28 | 9 | 3.2 | 65 | 36 | 8.4 | 117 | 75 | 13.6 | 160 | 108 | |||

| 0.78 | 30 | 10 | 3.3 | 65 | 36 | 8.5 | 117 | 75 | 13.7 | 160 | 108 | |||

| 0.8 | 30 | 10 | 3.4 | 70 | 39 | 8.6 | 125 | 81 | 13.8 | 160 | 108 | |||

| 0.82 | 30 | 10 | 3.5 | 70 | 39 | 8.7 | 125 | 81 | 13.9 | 160 | 108 | |||

| 0.85 | 30 | 10 | 3.6 | 70 | 39 | 8.8 | 125 | 81 | 14 | 160 | 108 | |||

| 0.85 | 32 | 11 | 3.7 | 70 | 39 | 8.9 | 125 | 81 | 14.25 | 169 | 114 | |||

| 0.9 | 32 | 11 | 3.8 | 75 | 43 | 9 | 125 | 81 | 14.5 | 169 | 114 | |||

| 0.92 | 32 | 11 | 3.9 | 75 | 43 | 9.1 | 125 | 81 | 14.75 | 169 | 114 | |||

| 0.95 | 32 | 11 | 4 | 75 | 43 | 9.2 | 125 | 81 | 15 | 169 | 114 | |||

| 0.98 | 34 | 12 | 4.1 | 75 | 43 | 9.3 | 125 | 81 | 15.25 | 178 | 120 | |||

| 1 | 34 | 12 | 4.2 | 75 | 43 | 9.4 | 125 | 81 | 15.5 | 178 | 120 | |||

| 1.05 | 34 | 12 | 4.3 | 80 | 47 | 9.5 | 125 | 81 | 15.75 | 178 | 120 | |||

| 1.1 | 36 | 14 | 4.4 | 80 | 47 | 9.6 | 125 | 81 | 16 | 178 | 120 | |||

| 1.15 | 36 | 14 | 4.5 | 80 | 47 | 9.7 | 133 | 87 | 16.25 | 184 | 125 | |||

| 1.2 | 38 | 16 | 4.6 | 80 | 47 | 9.8 | 133 | 87 | 16.5 | 184 | 125 | |||

| 1.25 | 38 | 16 | 4.7 | 86 | 47 | 9.9 | 133 | 87 | 16.75 | 184 | 125 | |||

| 1.3 | 38 | 16 | 4.8 | 86 | 52 | 10 | 133 | 87 | 17 | 184 | 125 | |||

| 1.35 | 40 | 16 | 4.9 | 86 | 52 | 10.1 | 133 | 87 | 17.25 | 191 | 130 | |||

| 1.4 | 40 | 18 | 5 | 86 | 52 | 10.2 | 133 | 87 | 17.5 | 191 | 130 | |||

| 1.45 | 40 | 18 | 5.1 | 86 | 52 | 10.3 | 133 | 87 | 17.75 | 191 | 130 | |||

| 1.5 | 40 | 18 | 5.2 | 86 | 52 | 10.4 | 133 | 87 | 18 | 191 | 130 | |||

| 1.55 | 43 | 20 | 5.3 | 86 | 52 | 10.5 | 133 | 87 | 18.25 | 198 | 135 | |||

| 1.6 | 43 | 20 | 5.4 | 93 | 57 | 10.6 | 133 | 87 | 18.5 | 198 | 135 | |||

| 1.65 | 43 | 20 | 5.5 | 93 | 57 | 10.7 | 142 | 94 | 18.75 | 198 | 135 | |||

| 1.7 | 43 | 20 | 5.6 | 93 | 57 | 10.8 | 142 | 94 | 19 | 198 | 135 | |||

| 1.75 | 46 | 22 | 5.7 | 93 | 57 | 10.9 | 142 | 94 | 19.25 | 205 | 140 | |||

| 1.8 | 46 | 22 | 5.8 | 93 | 57 | 11 | 142 | 94 | 19.5 | 2O5 | 140 | |||

| 1.85 | 46 | 22 | 5.9 | 93 | 57 | 11.1 | 142 | 94 | 19.75 | 205 | 140 | |||

| 1.9 | 46 | 22 | 6 | 93 | 57 | 11.2 | 142 | 94 | 20 | 205 | 140 | |||

| 1.95 | 49 | 24 | 6.1 | 101 | 63 | 11.3 | 142 | 94 |

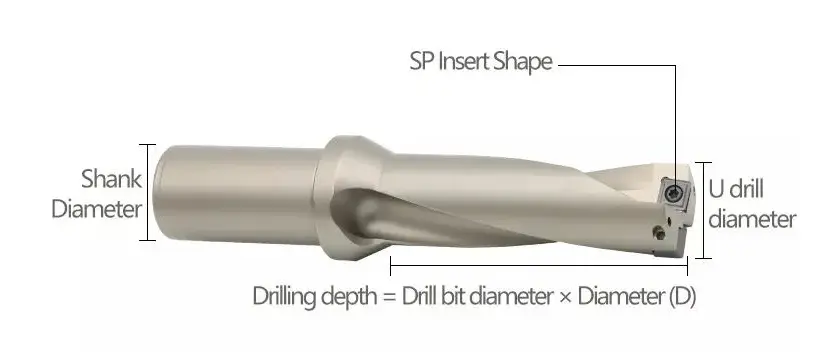

Indexable U Drills are designed for high-efficiency hole-making with replaceable cutting inserts, reducing downtime for sharpening. Featuring inserts at both central and peripheral edges, they ensure consistent performance and high material removal rates. The through-coolant design enhances chip evacuation and tool life, making them suitable for high-speed machining in materials like steel, cast iron, and non-ferrous metals. While highly effective in most applications, caution is needed with hard or brittle materials due to potential insert wear or breakage.

| Bit Diameter | Shank Diameter | Screw | Wrench | Matching Insert |

| 13-15 | 20MM | M2*5L | T6 | SPMG.050204 |

| 15.5-19 | 20MM | M2.2*5L | T6 | SPMG.060204 |

| 13-15.o | 25MM | M2*5L | T6 | SPMG.050204 |

| 15.5-21.5 | 25MM | M2.2*5L | T6 | SPMG.060204 |

| 22-25 | 25MM | M2.5*6L | T8 | SPMG.07T308 |

| 25.5-27.5 | 32MM | M2.5*6L | T8 | SPMG.07T308 |

| 28-28.5 | 32MM | M3.5*8L | T15 | SPMG.090408 |

| 29-33.5 | 32MM | M3.5*8L | T15 | SPMG.090408 |

| 34-39.5 | 32MM | M4*10L | T15 | SPMG.110408 |

| 40-41 | 40MM | M4*10L | T15 | SPMG.110408 |

| 42-45 | 40MM | M5*10L | T20 | SPMG.140512 |

| 46-50 | 40MM | M5*10L | T20 | SPMG.140512 |

| 51-55 | 40MM | M3.5*8L | T15 | SPMG.090408 |

| 56-60 | 40MM | M3.5*8L | T15 | SPMG.090408 |

| Bit Diameter | Shank Diameter | Screw | Wrench | Matching Insert |

| 14-19.5 | 25mm | M2.5*6L | T8 | WCM.O30208 |

| 20-23.5 | 25mm | M2.5*6L | T8 | WCM.040208 |

| 24-24.5 | 25mm | M3*7L | T8 | WCM.050208 |

| 25-30.5 | 32mm | M3*7L | T8 | WCM.050208 |

| 31-41.5 | 32mm | M3.5*10L | T15 | WCM.060208 |

| 42-62.5 | 40mm | M4*10L | T15 | WCM.O80208 |

| 63-70.5 | 40mm | M4*10L | T15 | WCM.O6T308 |

Welcome to our ODM/OEM service for non-standard DRILL BITS! We specialize in designing and manufacturing custom DRILL BITS to meet your unique needs, ensuring optimal performance and precision.