Product Specifications:

Product Number: HTJ639M12P125

Specification: M12*1.25

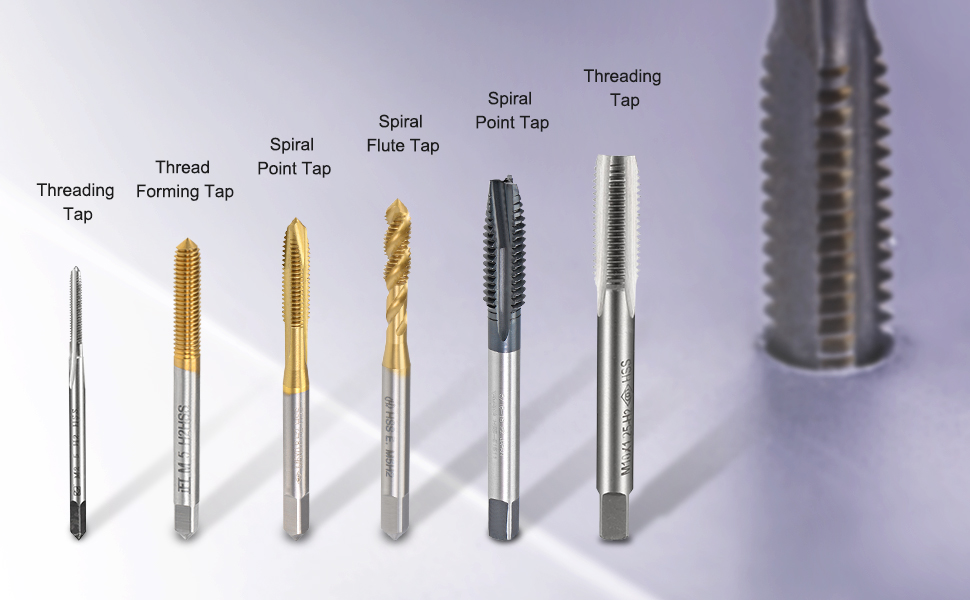

Type of Tap: Spiral Fluting Tap

Type of Die: Round Die

Material: High-speed Steel

Standard: Metric / British / American / JIS/DIN

Application for Machine Tool: Lathe

Application: Motorize / Manual

Customized: Customized

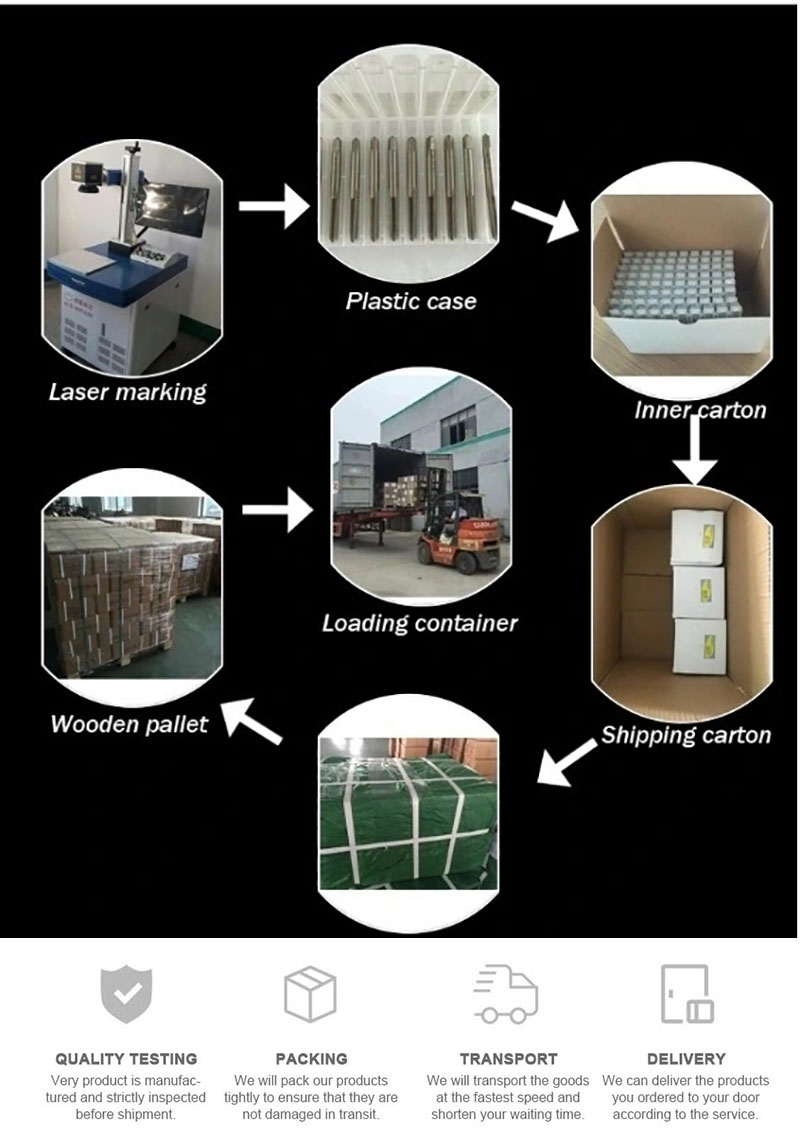

Transport Package: Plastic Box in Export Carton

Those taps are mainly used in mold manufacturing. The benefits that HSSE taps bring to us in mold manufacturing include: Suitable for High-Hardness Mold Steels, High-Temperature Stability Reduces Thermal Expansion, Improved Threading Precision, Increased Cutting Efficiency, Superior Surface Quality, Reduced Tool Change Frequency, Lower Production Costs and more.

HSSE taps play a crucial role in mold manufacturing, specifically in the following areas: Threaded Holes in Mold Bases and Accessories, Threaded Holes in Mold Cavities and Cores, Threaded Holes in Precision Mold Cavities, Threaded Holes in Complex Mold Components, Precision Thread Cutting for Mold Components and more.

By choosing the appropriate tap specifications and types, manufacturers can significantly improve machining efficiency and precision, especially in hard-to-machine materials and complex mold designs.

You can refer to the article Applications and Advantages of HSSE Taps in Mold Manufacturing to learn more.

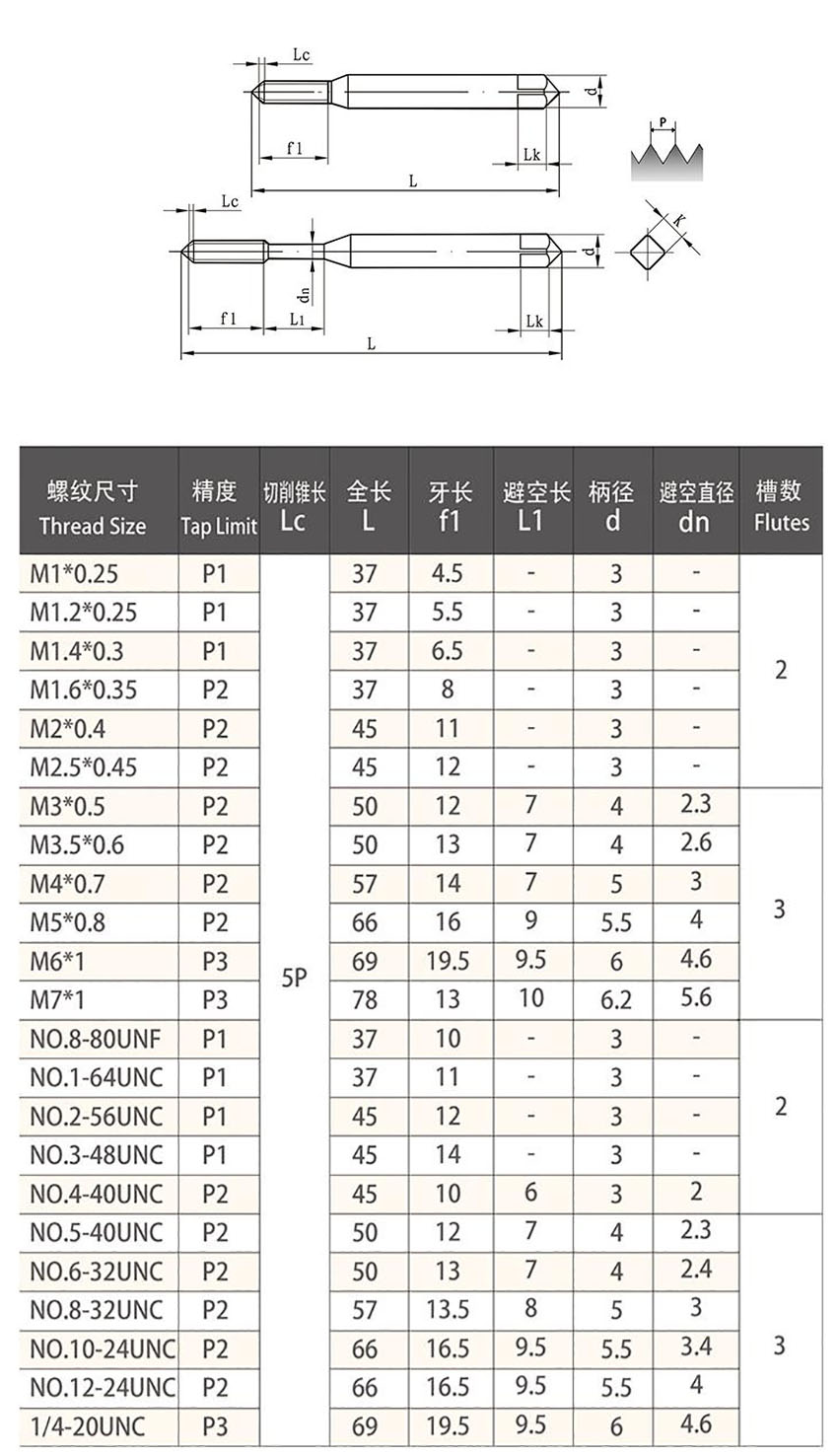

| Product Name | High Quality HSSE Taps |

| Flute Type | Straight Flute Taps / Spiral Flute Taps / Spiral Point Taps |

| Standard | Metric, JIS, DIN371 / DIN376 (ANSI Standard is Available) |

| Size | M1-M30 |

| Thread Type | M (MF, UNC, UNF, BSW, BSP are Available) |

| Material | HSSE |

| Process | Fully Ground |

| Shank Type | According to customer requirement |

| Surface Finish | Blank / Tin-Coated (Other High Performance Coating are Available) |

| Package | 10pcs in One PVC Pouch or in Plastic Box |

| Features | 1. Ideal for rethreading fasteners and fastener holes for auto and machinery repair. 2.Precision milled tap and die set for cutting raw material or repair existing threads, remove screws and more function. 3.It can improve the efficiency of processing thread, a necessary tool for hand tapping operation. 4.Suitable for variety of materials due to its chipless machining process. 5.Large center diameter of the tap leads to higher endurance and torsional strength, longer tool life, and not easily broken. |