Product Specifications:

Product Number: HTM3515DM10P125D

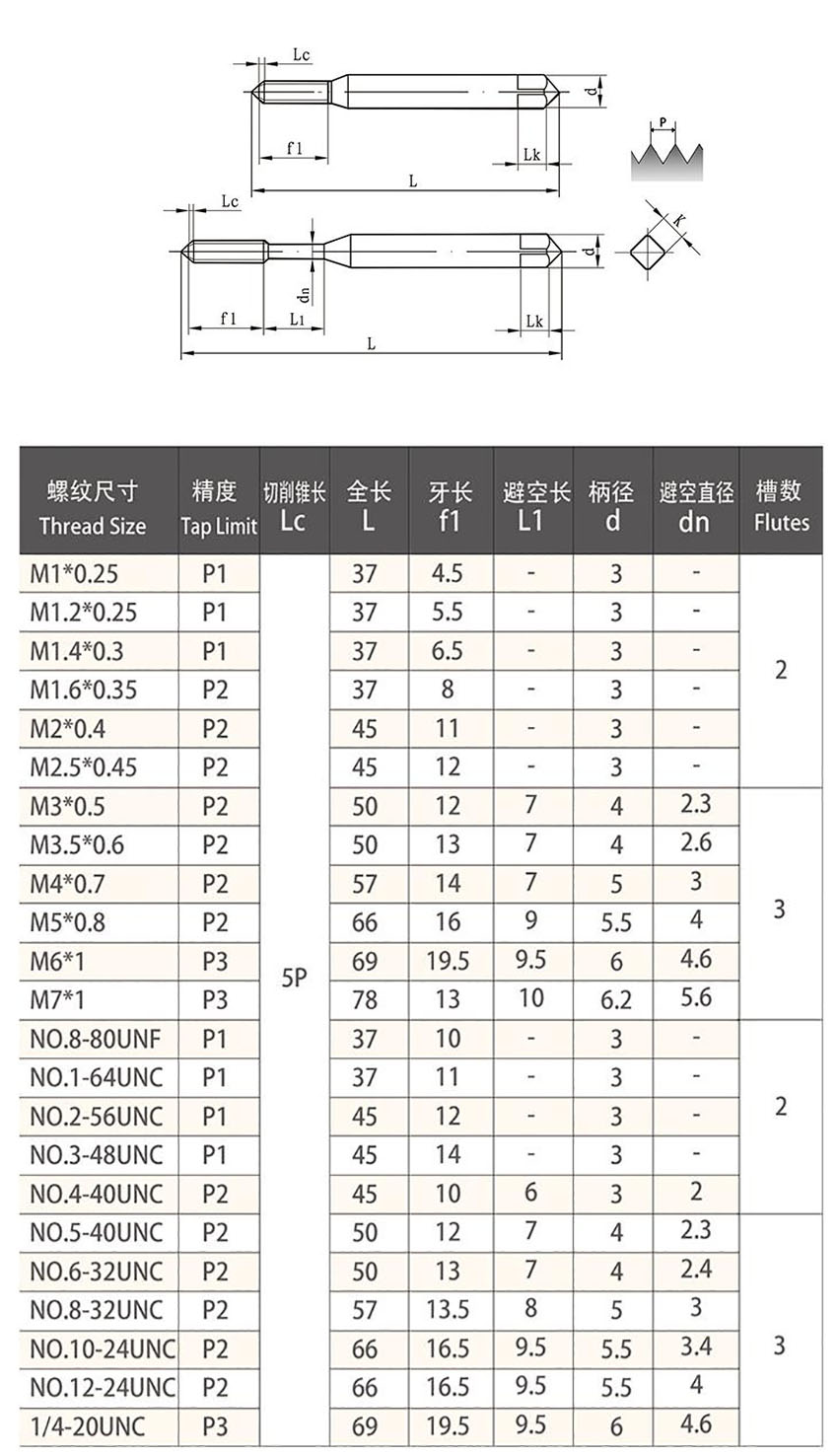

Specification: M35 DIN 15D M10*1.25

Spiral Angles: 15 degree

Type of Tap: Spiral Fluting Tap

Type of Die: Round Die

Material: High-speed Steel

Standard: Metric / British / American / JIS/DIN

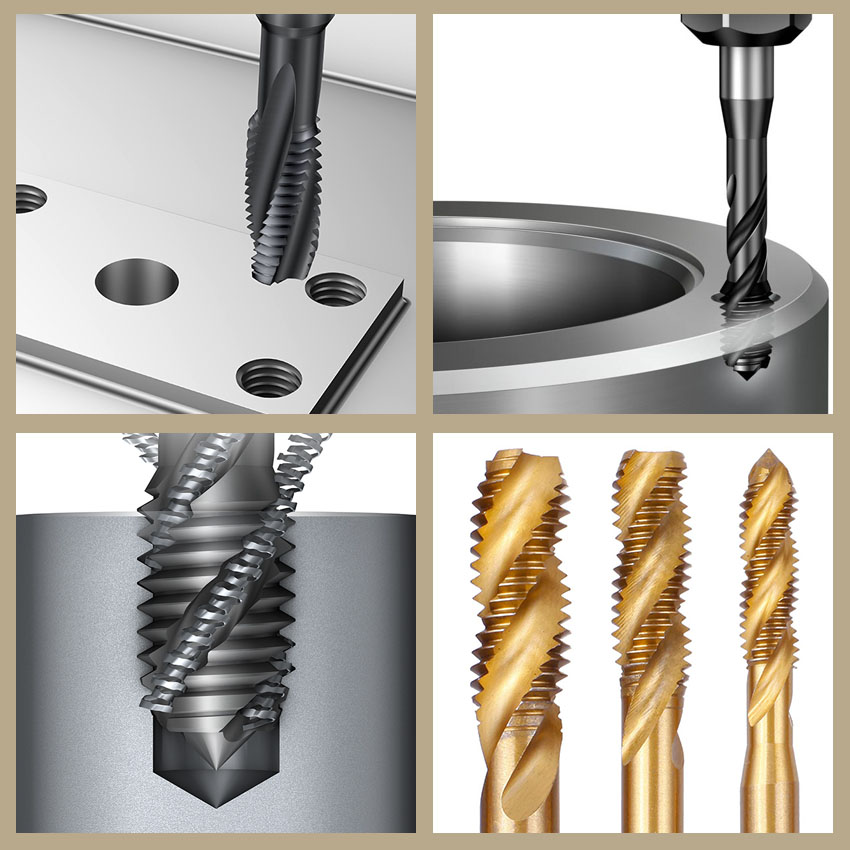

Application for Machine Tool: Lathe

Application: Motorize / Manual

Customized: Customized

Transport Package: Plastic Box in Export Carton

HSSE taps use the steels have a cobalt content of 5% or 8%, It is commonly believed that HSS-E steels are superior to normal HSS steels in all respects. HSSE Taps have excellent wear resistance and tool life. These results in fewer machine stoppages and reduced cost-per-hole. Long tool life reduces costs. HSSE Taps have superior process security, excellent thread quality. Optimized geometries allow for reliable, predictable tool life in both through and blind hole applications and optimized grades ensure low friction at high speeds for precision threads, resulting in excellent thread quality.

HSSE taps use the steels have a cobalt content of 5% or 8%, It is commonly believed that HSS-E steels are superior to normal HSS steels in all respects. HSSE Taps have excellent wear resistance and tool life. These results in fewer machine stoppages and reduced cost-per-hole. Long tool life reduces costs. HSSE Taps have superior process security, excellent thread quality. Optimized geometries allow for reliable, predictable tool life in both through and blind hole applications and optimized grades ensure low friction at high speeds for precision threads, resulting in excellent thread quality.

Advantages of HSSE due to the cobalt alloy:

Advantages of HSSE due to the cobalt alloy:

| Product Name | High Quality HSSE Taps |

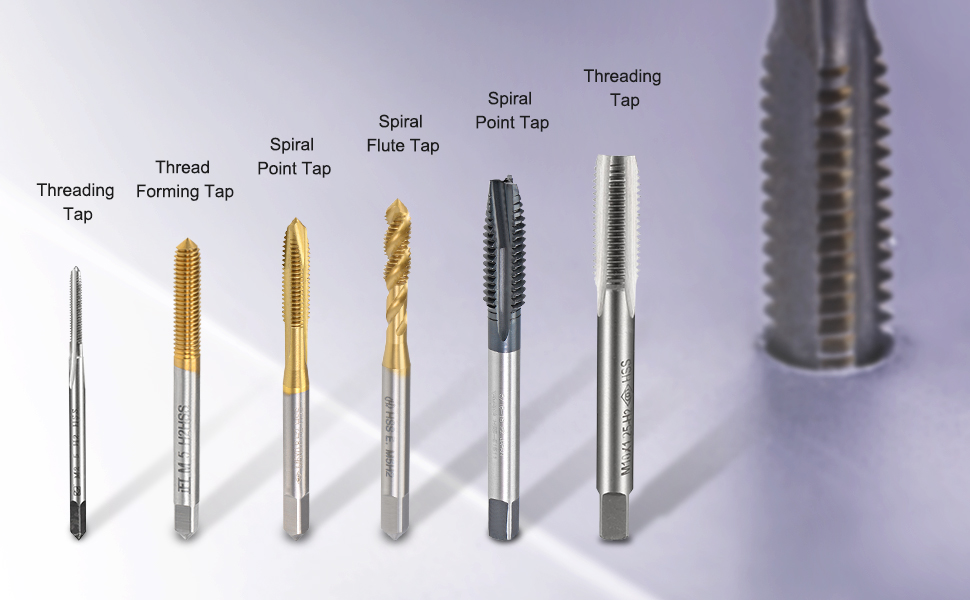

| Flute Type | Straight Flute Taps / Spiral Flute Taps / Spiral Point Taps |

| Standard | Metric, JIS, DIN371 / DIN376 (ANSI Standard is Available) |

| Size | M1-M30 |

| Thread Type | M (MF, UNC, UNF, BSW, BSP are Available) |

| Material | HSSE |

| Process | Fully Ground |

| Shank Type | According to customer requirement |

| Surface Finish | Blank / Tin-Coated (Other High Performance Coating are Available) |

| Package | 10pcs in One PVC Pouch or in Plastic Box |

| Features | 1. Ideal for rethreading fasteners and fastener holes for auto and machinery repair. 2.Precision milled tap and die set for cutting raw material or repair existing threads, remove screws and more function. 3.It can improve the efficiency of processing thread, a necessary tool for hand tapping operation. 4.Suitable for variety of materials due to its chipless machining process. 5.Large center diameter of the tap leads to higher endurance and torsional strength, longer tool life, and not easily broken. |