Product Specifications:

Product Number: HTA29M16P200L110T

Specification: A29 M16*2.0*110 TIN

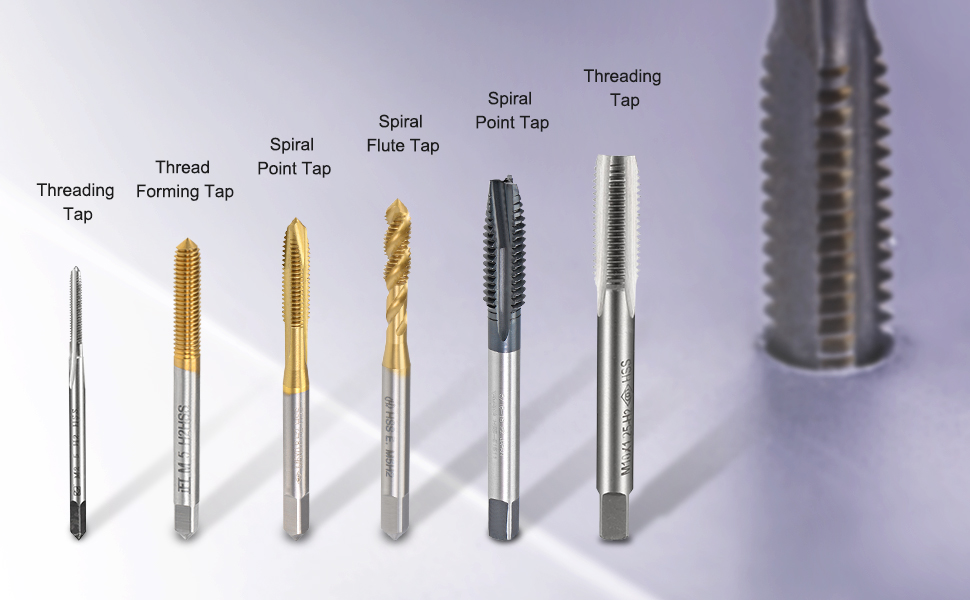

Type of Tap: Spiral Fluting Tap

Type of Die: Round Die

Material: High-speed Steel

Standard: Metric / British / American / JIS/DIN

Application for Machine Tool: Lathe

Application: Motorize / Manual

Customized: Customized

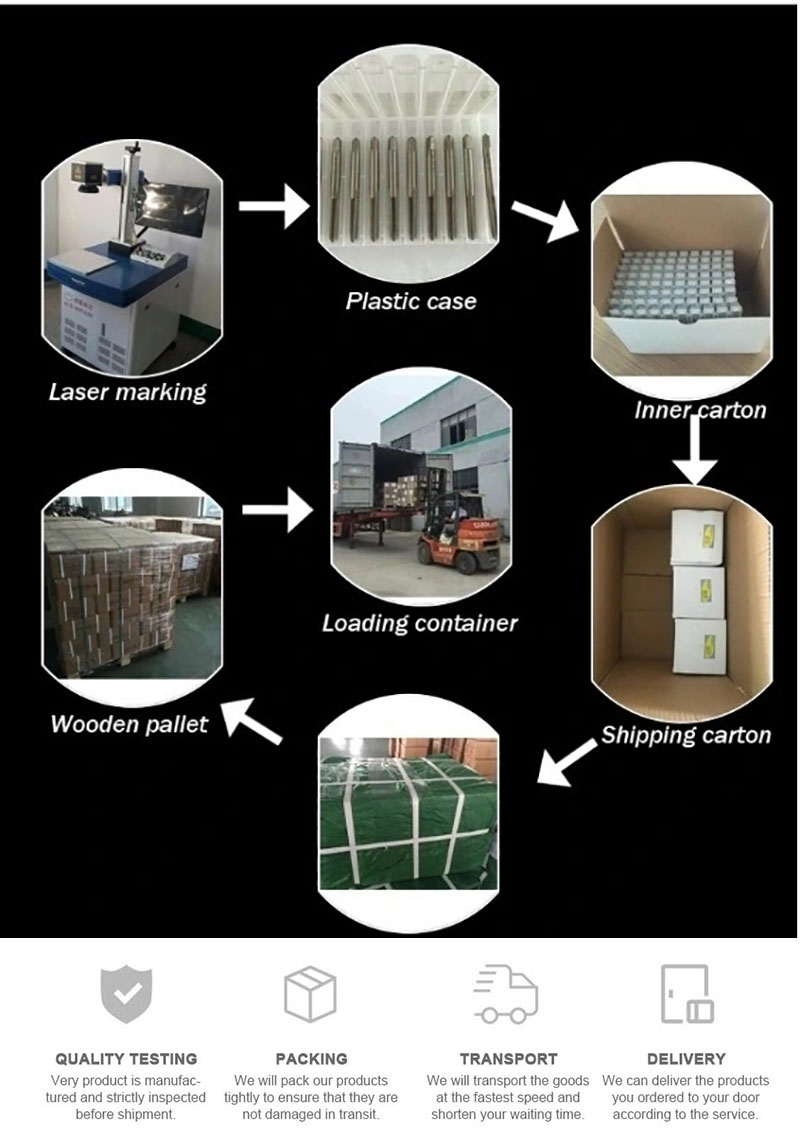

Transport Package: Plastic Box in Export Carton

Those taps are mainly used in mechanical manufacturing. The benefits that HSSE taps bring to us in mechanical manufacturing include: Enhanced Tool Life, High Heat Resistance, Improved Cutting Performance, Versatility, Ensures that threaded holes meet requird Precision and Accuracy, higher Cost-Effectiveness, Better Surface Finish and more.

HSSE taps play a crucial role in mechanical manufacturing, specifically in the following areas: mechanical transmission parts, bearing housings, pumps and valve bodies, supports and frames, conveyor equipment, fasteners, and connecting components in mechanical devices.

The advantages of HSSE taps in mechanical manufacturing extend beyond just wear resistance and heat tolerance. Their cutting performance, versatility, precision, and cost-effectiveness make them an essential tool for improving production efficiency and product quality. Specific applications illustrate how HSSE taps can significantly enhance the manufacturing process, making them indispensable in the field of mechanical engineering.

You can refer to the article Advantages of HSSE Taps in Mechanical Manufacturing to learn more.

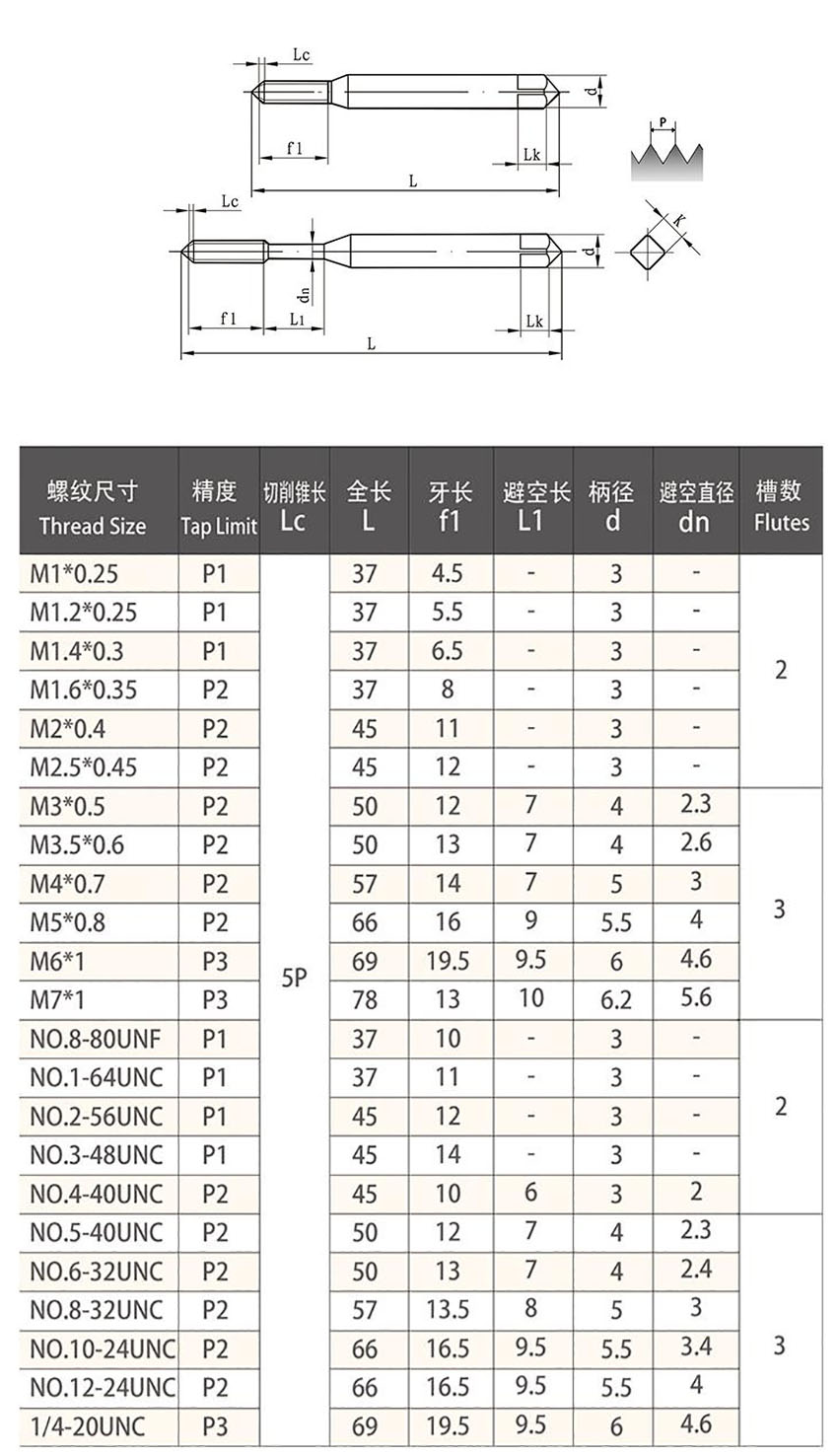

| Product Name | High Quality HSSE Taps |

| Flute Type | Straight Flute Taps / Spiral Flute Taps / Spiral Point Taps |

| Standard | Metric, JIS, DIN371 / DIN376 (ANSI Standard is Available) |

| Size | M1-M30 |

| Thread Type | M (MF, UNC, UNF, BSW, BSP are Available) |

| Material | HSSE |

| Process | Fully Ground |

| Shank Type | According to customer requirement |

| Surface Finish | Blank / Tin-Coated (Other High Performance Coating are Available) |

| Package | 10pcs in One PVC Pouch or in Plastic Box |

| Features | 1. Ideal for rethreading fasteners and fastener holes for auto and machinery repair. 2.Precision milled tap and die set for cutting raw material or repair existing threads, remove screws and more function. 3.It can improve the efficiency of processing thread, a necessary tool for hand tapping operation. 4.Suitable for variety of materials due to its chipless machining process. 5.Large center diameter of the tap leads to higher endurance and torsional strength, longer tool life, and not easily broken. |