Product Specifications:

Product Number: TCD165073D180123T

Material:Tungsten Carbide

Specification: D16.5*73*D18*123

Coating: TiN

HRC: 45-68

Length:Jobber-length

Customized:Customized

Standard:DIN / JIS / / API

Transport Package:Plastic Box

Insert: Spmg Spgt

Machining Type: CNC Machine

Customized Support: OEM, ODM, OBM

Usage:Wood Drilling / PCB Drilling / Metal Drilling / Masonry Drilling

HS Code: 8207400000

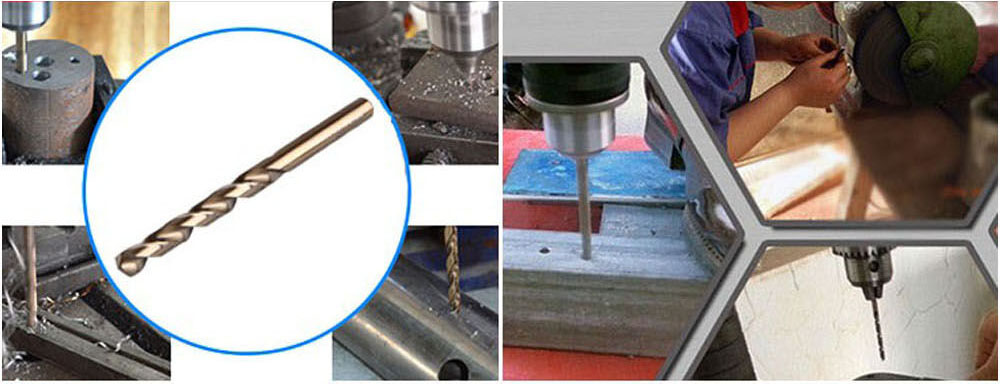

This set of solid carbide drill bits are mainly used in automobile manufacturing. The benefits that solid carbide drill bits bring to us in automobile manufacturing include: High Precision Hole Machining, Excellent Wear Resistance, Higher Cutting Speeds, Good Thermal Stability, Strong Versatility, Reduced Cutting Forces, Improved Surface Quality.

SOLID CARBIDE DRILLS play a crucial role in automotive processing, specifically in the following areas: Engine Cylinder Machining, Precision Machining of Oil and Cooling Holes, Machining of Crankshafts and Camshafts, Machining of Transmission Housings and Components, Machining of Body Structure Components, Machining of Brake System Components, Machining of Battery and Electric Motor Components.

Solid carbide drills are widely used in critical aspects of automotive processing due to their superior performance, enhancing machining efficiency and product quality while ensuring vehicle performance and safety.

You can refer to the article The Critical Role of Solid Carbide Drills in Automotive Processing to learn more.

D18.5*60*D20*100

D18.5*60*D20*100

D16.2*60*D18*100

D16.2*60*D18*100

D17.3х60хD18х123

D17.3х60хD18х123

D14.5*65*D16*115

D14.5*65*D16*115

D16.8*73*D18*123

D16.8*73*D18*123

D17.2*60*D18*100

D17.2*60*D18*100

D13.2*60*D14*107

D13.2*60*D14*107

D14.5*56*D14.5*107_2F

D14.5*56*D14.5*107_2F

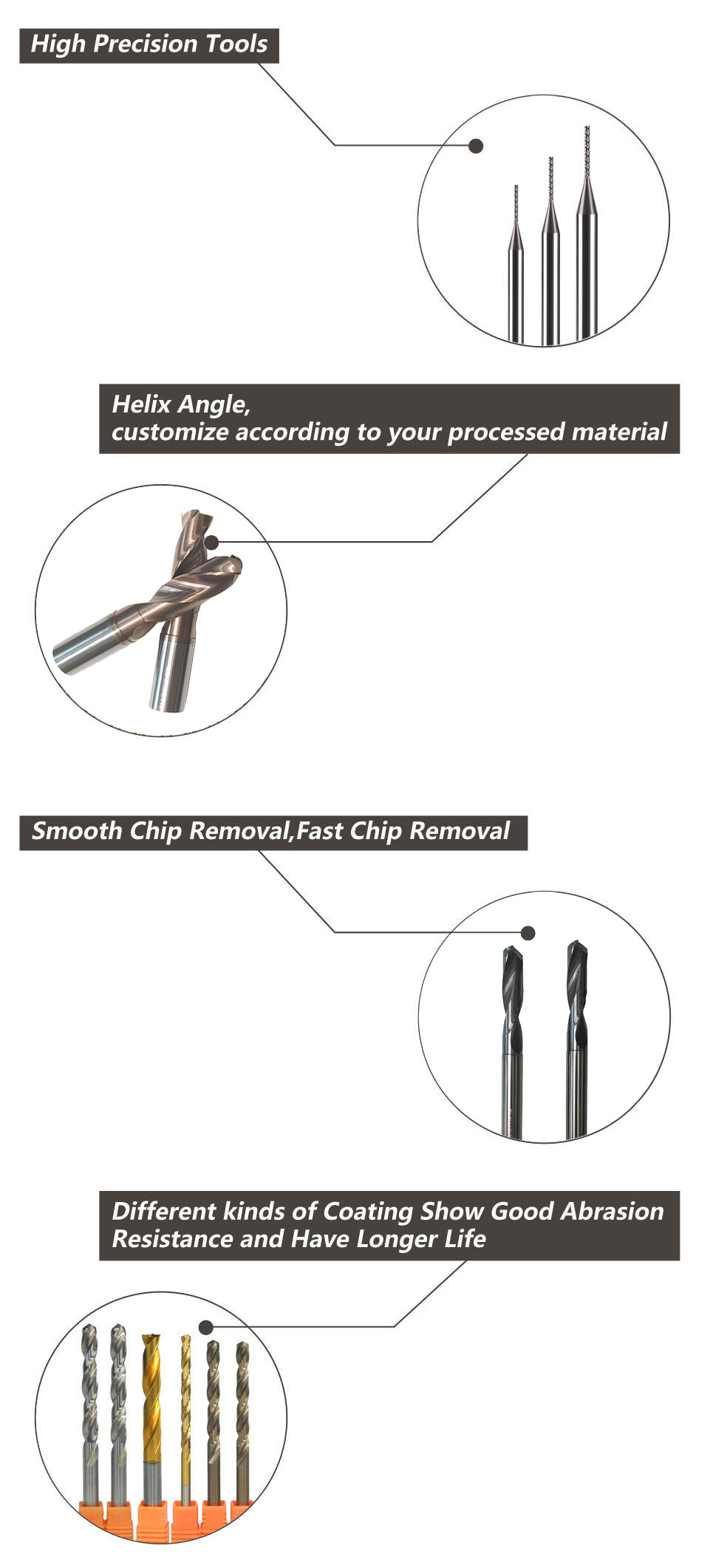

| Name: | Drill | Material: | Solid Carbide/HSSE/HSS |

| Flute Dia: | 0.1~40mm | HRC: | HRC45°,HRC50°,HRC55°,HRC58°,HRC60°,HRC65° |

| Shank Dia: | 3~40mm | Coating: | AITiN, TiAIN, TiAISi, TiSiN, TiN, DLC, Nano, Diamond |

| Total Length: | 38~330mm | Precision: | 0.005~0.01mm |

| Process Equipment : | CNC Tooling | Suitable For: | Carbon Steel, Alloy Steel, High Alloy Steel, Tool Steel, Structural Steel, Aluminum, Copper, Plastic, Acrylic, PVC, Wood, Titanium |

Tungsten Carbide Twist Drill

Tungsten Carbide Twist Drill

Scope of Application:

Scope of Application:

Twist drill bits are widely used to drill stainless steel, aluminum, copper, steel, metal and other metals. They are suitable for timber, PVC materials cutting as well.

Our advantages:

Twist drill bits are widely used to drill stainless steel, aluminum, copper, steel, metal and other metals. They are suitable for timber, PVC materials cutting as well.

Our advantages:

-Express companies: FedEx, DHL, TNT, UPS, etc.

-Airlines.

-Ocean shipping

Standard packing

-Plastic boxes with foam inside and carton outside.

-Paper boxes with foam inside and carton outside.

-Inner boxes/packing material inside and plywood box outside (for heavy product).

-Express companies: FedEx, DHL, TNT, UPS, etc.

-Airlines.

-Ocean shipping

Standard packing

-Plastic boxes with foam inside and carton outside.

-Paper boxes with foam inside and carton outside.

-Inner boxes/packing material inside and plywood box outside (for heavy product).