From Tesla to BYD: The Manufacturing Secrets Behind Solid Tungsten Carbide Drill Bits

On the production line of Tesla’s Shanghai Gigafactory, an electric motor housing is precisely drilled every 22 seconds—an astonishing feat enabled by a single CNY 380 solid tungsten carbide drill bit. As the push for lightweight materials reshapes the automotive industry and smart factories demand micron-level precision, traditional drill bits are undergoing an unprecedented evolution. This article unveils the silent yet critical technological transformation behind this shift and explains why 17 of the world’s top 20 automakers have already incorporated solid tungsten carbide drill bits into their strategic procurement plans.

The Drilling Battle on Automotive Production Lines

1. The Machining Challenges of New Materials

- The "Soft Trap" of Aluminum

- The aluminum content in EVs has surged, reaching 280 kg per vehicle in 2024.

- Cutting edge wear comparison: Ordinary drill bit accumulates aluminum buildup after 50 uses vs. Solid tungsten carbide drill bit remains clean after 300 uses.

- The "Strength Curse" of High-Strength Steel

- Hot-formed steel can reach 550 HV, twice the hardness of conventional steel, leading to work hardening.

- Case study: A brake disc supplier using high-speed steel drill bits achieved an average lifespan of only 80 holes. After switching to solid tungsten carbide, tool life increased to 600 holes.

- The Delamination Crisis of Composite Materials

- Illustration: Layer separation defects in CFRP drilling.

- Solution from a battery housing supplier: Special cutting edge design + segmented feed strategy to improve yield rates.

2. The Race for Precision and Efficiency

- The Precision Red Line in EV Powertrain Systems Motor shaft hole perpendicularity requirement: ≤0.03° per 100mm (equivalent to a flagpole five stories high tilting less than the thickness of a coin). Case: An EV control box requiring hole pitch tolerance of ±0.02mm—one-fourth the thickness of an A4 sheet.

- The Efficiency Pressure on Traditional Automakers A Japanese automaker optimized its gearbox drilling parameters, reducing cycle time from 43 seconds to 29 seconds per part.

3. Hidden Cost Pitfalls (New Perspective)

- Downtime Loss Calculator Formula: Hourly loss = machine depreciation + labor costs + delay penalties Example: A stamping workshop loses CNY 380 per tool change.

- Scrap Chain Reaction Case: A steering knuckle drilling error led to an entire batch being scrapped, causing a direct loss of over CNY 200,000.

- Compliance Challenges Under New Environmental Regulations GB/T 39199-2020: The latest national standard for metal dust emission control.

Five Must-Have Capabilities of a High-Performance Drill Bit

1. Wear Resistance & Durability

Test results: On the same steel plate, an ordinary drill bit wears out after 50 holes, whereas a solid tungsten carbide drill bit lasts for 800 holes.

2. Precision & Stability

Case: A gear manufacturer improved its hole position pass rate from 92% to 99.6% after adopting solid carbide drill bits.

3. Intelligent Chip Evacuation

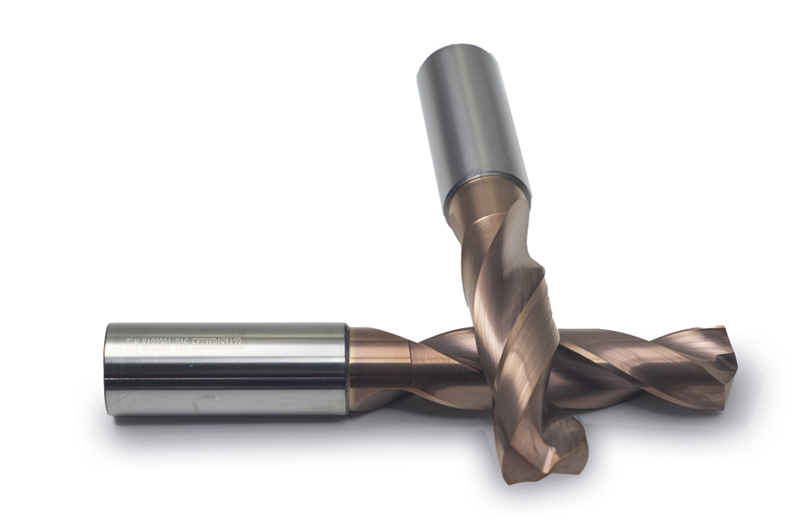

The helical flute design enables automatic chip evacuation, preventing scratches on workpieces.

4. Versatility Across Materials

A single carbide drill bit can machine aluminum alloys, stainless steel, and composites.

5. Time & Cost Savings

Example calculation: 230 hours of tool change time saved annually per production line.

The Evolution of Solid Tungsten Carbide Drill Bits

1. Cutting-Edge Material Science

- The Secret of Gradient Structures Grain composition: Ultra-fine surface grains (0.3±0.05µm): Provide hardness Coarse core grains (1.0–1.2µm): Ensure toughness

- The Evolution of Coatings TiN (Gold) → TiAlN (Purple-Black) → AlCrN (Blue-Gray) Comparative chart illustrating the enhanced wear resistance across three generations.

2. The Intelligence in Geometric Design

- The Mystery of Drill Point Angles 130° tip angle: Best for stainless steel 140° tip angle: Optimized for cast iron 150° tip angle: Designed for composite materials

- The Fluid Dynamics of Helical Flutes Video analysis: Why a 45° helix angle evacuates chips 3x faster than a 30° angle.

3. Smart Technology Integration

- Cloud-Based Tool Monitoring Real-time current signal tracking detects abnormal wear before failure.

- AI-Powered Grinding Systems Automated tool regrinding restores 90% of original tool life.

Real-World Case Studies in Automotive Factories

1. EV Battery Pack Machining

Challenge: 2mm stacked aluminum sheet deformation during drilling.

Solution: Custom short-edge solid carbide drill bit + dedicated cooling strategy.

Outcome: 2x faster processing speed, 80% reduction in deformation.

2. Deep-Hole Machining in Engine Blocks

Problem: 6mm diameter, 120mm deep oil passage holes prone to deviation.

Solution: Extended drill rods with guide heads.

Result: Hole straightness improved to 0.003mm per 100mm, the industry’s highest standard.

3. Car Door Hinge Drilling

Pain Point: Standard drill bits failing 15 times per month.

Improvement: Reinforced drill tip structure.

Savings: 60% reduction in tool replacement costs.

Conclusion

As the automotive industry races toward electrification and intelligence, innovations in solid tungsten carbide drill bits are redefining manufacturing benchmarks. Whether it’s a 0.1% increase in yield rate or a 15-second reduction in tool change time, these incremental breakthroughs collectively forge China’s manufacturing competitiveness on the global stage.

OEM Capability

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands. Categories

| HSS-PM Taps | HSSE-M42 Taps |

| HSSE / HSS Taps | Spiral Flute Taps |

| Straight Flute Taps | Spiral Point Taps |

| Multi-function Taps |

| Solid Carbide Drill Bits | Twist Drill Bits |

| Center Drill Bits | Indexable U Drills |

| Flat-end Milling Cutter | Ball Nose End Mills |