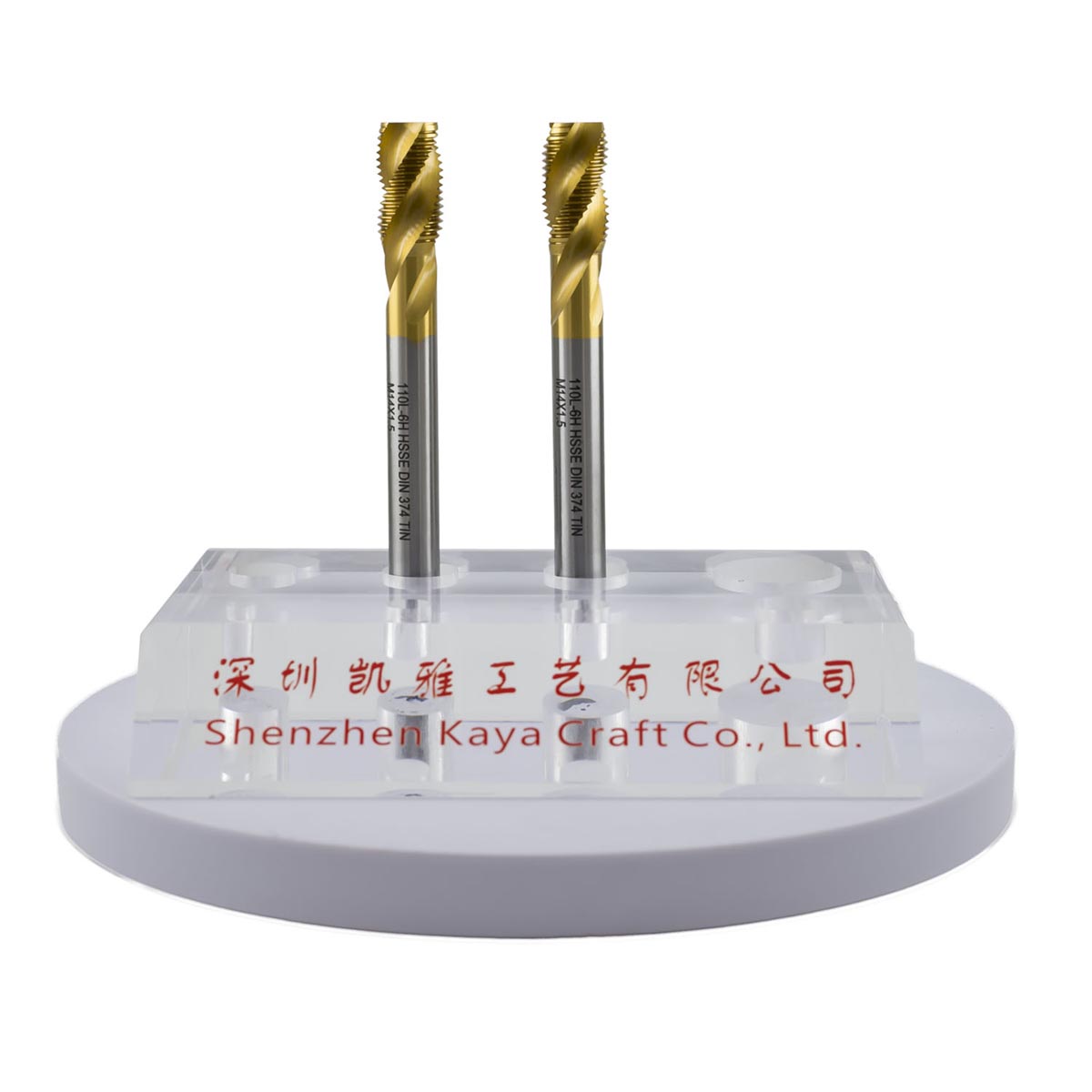

Applications of Coated Taps in High-Temperature and Dry Cutting Conditions

Coated taps are widely used in high-temperature and dry cutting conditions due to their ability to improve tool durability, wear resistance, and cutting performance. The coatings provide additional protection, reduce cutting forces, manage heat generation, and enhance cutting quality in environments where coolant is not used or when temperatures are high. Below are the main applications and advantages of coated taps in high-temperature and dry cutting:

1. High-Temperature Resistance

Coatings like TiN, TiAlN, and AlCrN provide excellent high-temperature resistance. For example, TiAlN and AlCrN coatings can withstand temperatures up to 900°C or even 1000°C, which is critical for high-temperature dry cutting. The coatings help reduce tool wear and adhesion at high temperatures.

2. Reduced Friction and Heat

Coatings with low friction coefficients, such as TiN and TiAlN, help reduce the friction between the tap and the workpiece, minimizing the heat generated during cutting. This is particularly important in dry cutting, where the absence of coolant makes heat management more critical. Lower friction also improves cutting efficiency and extends tool life.

3. Improved Cutting Stability

Coated taps maintain better cutting stability under high temperatures and dry cutting conditions. The coatings reduce thermal deformation and tool failure, ensuring stable cutting performance over extended periods. In high-load and high-speed cutting, the coated tap can maintain tool life and machining precision.

4. Oxidation and Corrosion Resistance

Taps are prone to oxidation and corrosion, especially under high temperatures or in dry cutting without coolant. Coated taps provide superior oxidation protection. For example, TiAlN coatings offer excellent oxidation resistance, preventing the surface of the tap from degrading in high-temperature environments and extending tool life.

5. Adaptation to Difficult-to-Cut Materials

Difficult-to-machine materials, such as high-temperature alloys, titanium alloys, and stainless steels, often require high cutting temperatures and are challenging to process in dry cutting conditions. Coated taps, with their excellent high-temperature resistance, wear resistance, and oxidation resistance, are ideal for processing these hard-to-machine materials.

6. Coolant-Free Machining

In dry cutting, where coolant or lubricants cannot be used, coated taps maintain lower cutting forces, reducing heat buildup and friction. This helps improve machining efficiency and surface quality, even without the cooling and lubrication support that typically reduces cutting temperatures.

7. Reduced Cutting Forces

Coated taps effectively reduce cutting forces in high-temperature and dry cutting conditions. Lower cutting forces help minimize thermal deformation, tool wear, and damage to the workpiece. This is especially important when machining high-hardness materials, as it ensures a stable and efficient cutting process.

8. Extended Tool Life

The wear resistance and high-temperature resistance of coated taps significantly extend their lifespan. Under high-temperature and dry cutting conditions, the coatings protect the taps from continuous wear, preventing premature failure. This reduces production costs and increases overall production efficiency.

Application Examples:

Aerospace and Automotive Industries: Coated taps are frequently used in these sectors for machining high-strength, heat-resistant alloys. They maintain tool stability and longevity in dry cutting environments.

Precision Mold Manufacturing: Coated taps are commonly used in mold manufacturing, especially for machining hardened steels, titanium alloys, and other hard materials. The coatings ensure high precision and durability under high-load, dry cutting conditions.

Medical Device Manufacturing: In medical device manufacturing, materials like stainless steel and titanium are often machined under high temperatures and dry cutting conditions. Coated taps provide excellent heat stability and wear resistance, ensuring high-quality machining results.

TiN, TiAlN, and AlCrN are commonly used coating materials, each offering distinct advantages in terms of hardness, high-temperature performance, oxidation resistance, and wear resistance. These coatings are tailored for specific cutting conditions. Below is a comparison of their performance:

1. TiN (Titanium Nitride) Coating

Hardness: TiN has a moderate hardness of about 2000 HV, making it suitable for general machining applications where moderate wear resistance is required.

High-Temperature Resistance: TiN can withstand temperatures up to around 500°C. It performs well at medium temperatures but has limited high-temperature stability.

Oxidation Resistance: TiN has good oxidation resistance at lower temperatures. However, it may start to degrade and oxidize at higher temperatures.

Applications: TiN is commonly used for machining mild steel, cast iron, and copper alloys, making it suitable for standard cutting operations, especially on low-alloy steels and cast iron.

2. TiAlN (Titanium Aluminum Nitride) Coating

Hardness: TiAlN coatings have a higher hardness, ranging from 2800 to 3000 HV, offering superior wear resistance and fatigue strength compared to TiN. This makes it ideal for high-load cutting applications.

High-Temperature Resistance: TiAlN excels in high-temperature environments, typically withstanding temperatures up to 900°C. Some advanced TiAlN coatings can endure even higher temperatures, making it ideal for high-speed cutting and dry cutting applications.

Oxidation Resistance: TiAlN provides excellent oxidation resistance, preventing degradation at elevated temperatures and ensuring stable tool performance under harsh conditions.

Applications: TiAlN is commonly used for high-speed cutting, machining difficult materials such as stainless steels, titanium alloys, and hardened steels. It is especially effective in high-temperature, dry cutting, and high-speed cutting operations.

3. AlCrN (Aluminum Chromium Nitride) Coating

Hardness: AlCrN coatings are the hardest of the three, typically exceeding 3000 HV. Its exceptional hardness and wear resistance make it ideal for extreme cutting conditions, particularly at very high temperatures.

High-Temperature Resistance: AlCrN outperforms TiN and TiAlN in terms of high-temperature resistance, typically withstanding temperatures up to 1000°C or higher. This makes it ideal for cutting in extremely high-temperature environments.

Oxidation Resistance: AlCrN provides superior oxidation resistance, remaining stable even at very high temperatures and offering exceptional durability under heat stress.

Applications: AlCrN coatings are ideal for extreme high-temperature, dry cutting, and high-load machining operations. They are used for cutting high-temperature alloys, hard materials, stainless steel, and aerospace-grade components, where superior high-temperature performance is required.

Performance Comparison Summary

| Property | TiN | TiAlN | AlCrN |

|---|---|---|---|

| Hardness | Moderate (2000 HV) | High (2800-3000 HV) | Very High (3000+ HV) |

| High-Temperature | ResistanceGood (up to 500°C) | Excellent (up to 900°C) | Exceptional (up to 1000°C+) |

| Oxidation Resistance | Good | Excellent | Superior |

| Friction Coefficient | Low | Low | Low |

| Applications | General machining of mild steel and cast iron | High-speed and dry cutting of tough materials like stainless steel and titanium alloys | Extreme high-temperature cutting of high-performance alloys, stainless steels, and aerospace materials |

| Key Features | Good wear and corrosion resistance | Superior high-temperature stability and wear resistance | Exceptional oxidation resistance and high-temperature performance |

Selection Recommendations:

TiN: Ideal for general machining of mild steel, cast iron, and non-ferrous materials. Suitable for medium-temperature applications but not recommended for high-temperature or dry cutting environments.

TiAlN: Best suited for high-speed cutting, dry cutting, and high-temperature applications. It excels in tough-to-machine materials like stainless steel, titanium alloys, and hardened steels.

AlCrN: Perfect for extreme high-temperature, dry cutting, and high-load operations. Ideal for cutting high-temperature alloys, hard materials, and aerospace components due to its outstanding heat resistance and wear resistance.

Coated taps are highly effective in high-temperature and dry cutting applications, significantly improving cutting stability, tool life, and efficiency. By selecting appropriate coatings (e.g., TiAlN, AlCrN), coated taps can deliver exceptional performance under extreme cutting conditions, making them ideal for machining difficult-to-cut materials such as high-temperature alloys, hard steels, and precision parts.

OEM Capability

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands. Categories

| HSS-PM Taps | HSSE-M42 Taps |

| HSSE / HSS Taps | Spiral Flute Taps |

| Straight Flute Taps | Spiral Point Taps |

| Multi-function Taps |

| Solid Carbide Drill Bits | Twist Drill Bits |

| Center Drill Bits | Indexable U Drills |

| Flat-end Milling Cutter | Ball Nose End Mills |