Customized Coating Solutions for Precision Cutting Tools

In the competitive battlefield of high-end manufacturing, the multilayer structure of cutting tool coatings is silently redefining machining rules. As the performance of single-layer coatings nears its physical limits, nanometer-scale multilayer architectures—offering stress regulation, functional integration, and defect blocking—have emerged as the key to overcoming machining challenges in aerospace, new energy vehicles, and other advanced industries.

1. The Scientific Logic Behind Coating Selection

1.1 The Four Core Functions of Tool Coatings

- Protective Shield: Forms a 2-5μm protective layer on the tool surface (equivalent to 1/20 the thickness of a human hair).

- Lubrication Layer: Some coatings have a friction coefficient as low as 0.15, approaching the slipperiness of ice.

- Heat Dissipation: Certain coatings can reduce cutting temperatures by over 200°C.

- Wear Indicator: The wear state of the coating directly reflects whether machining parameters are optimized.

HSSE TAP WITH TIN COATING

1.2 The Golden Formula for Material & Coating Pairing

| Machined Material | Recommended Coating | Key Performance Enhancement | Typical Application |

|---|

| Stainless Steel | TiAlCrN + MoS₂ | Anti-adhesion, corrosion resistance | Food machinery parts |

| Titanium Alloy | AlCrN + WS₂ | Anti-diffusion, low friction | Aerospace fastener manufacturing |

| Aluminum Alloy | CrN + DLC | Anti-built-up edge, surface smoothness | Automotive engine blocks |

| Composite Materials | Multilayer gradient coating | Anti-chipping, stress buffering | Wind turbine blade drilling |

|

SOLID CARBIDE DRILL BITS WITH TiAlN COATING

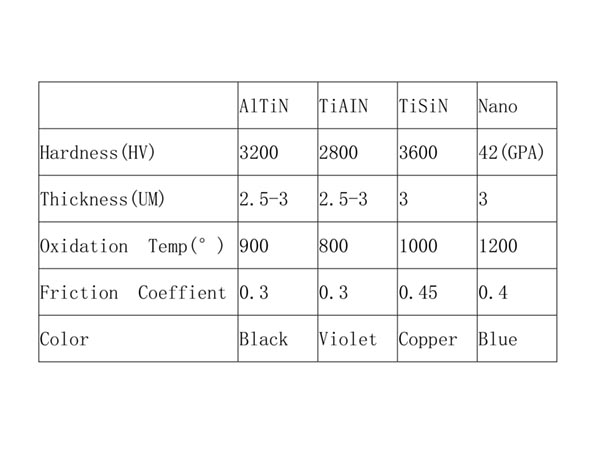

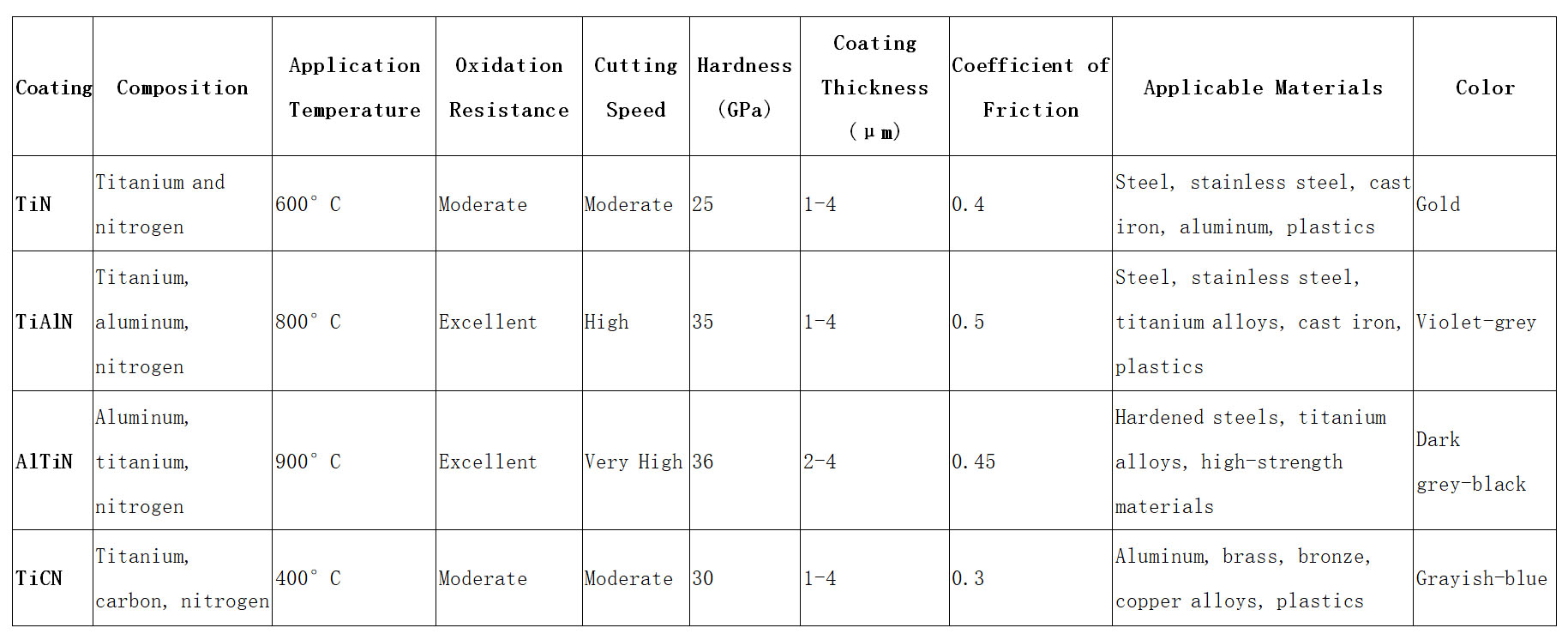

2. Comparison of Common Coatings

3. Key Technological Points in Coating Processes

3.1 Inside the Vacuum Coating Facility

- Pre-treatment:

- Plasma Cleaning (removes nanometer-scale contaminants).

- Argon Ion Bombardment (enhances surface activation).

- Deposition Process:

- Temperature Control: 350-450°C (ensures HSS hardness remains unaffected).

- Pressure Control: 0.3-0.5Pa (equivalent to the air pressure at the summit of Mount Everest).

- Time Control: 2-4 hours (each micron requires 30-50 minutes).

- Post-treatment:

- Micro-sandblasting (enhances coating adhesion).

- Passivation Treatment (improves corrosion resistance).

3.2 Three-Layer Quality Assurance System

- Laboratory Testing:

- ✔ Scratch Test: Withstands 5kg pressure without peeling.

- ✔ Salt Spray Test: 720 hours without rust.

- ✔ Metallographic Analysis: Examined under 2000x magnification.

- On-Site Validation:

- ✔ Continuous Machining Test: Tracks tool lifespan curve.

- ✔ Chip Morphology Analysis: Evaluates coating condition.

- Customer Tracking:

- ✔ Tool Life Database: Accumulated 100,000+ machining data points.

4. The Design Philosophy of Multilayer Coatings

4.1 Why Use a Layered "Cake-Like" Structure?

- Stress Buffering: Hard layers (e.g., AlTiN) alternate with soft layers (e.g., MoS₂) to distribute cutting impact forces.

- Functional Segmentation:

- Wear-resistant outer layer (2μm TiCN)

- Heat insulation middle layer (1.5μm Al₂O₃)

- High-adhesion base layer (0.5μm CrN)

- Defect Blocking: Each layer is ≤1μm thick, preventing crack propagation.

4.2 Typical Multilayer Coating Designs

| Structure Type | Layers | Total Thickness | Application | Performance Enhancement |

|---|

| Gradient Structure | 5-8 | 3-5μm | Stainless steel interrupted cutting | Anti-chipping +40% |

| Nanolayered | 50+ | 2-3μm | Titanium alloy finishing | Friction coefficient ↓35% |

| Soft-Hard Alternating | 10-15 | 4-6μm | Composite material drilling | Tool life ↑300% |

| Functional Composite | 3-5 | 5-8μm | High-temperature alloy milling | Heat resistance ↑200°C |

|

5. Real-World Coating Applications

5.1 European Automotive Parts Order Breakthrough

- Customer Pain Points:

Machining VW DQ200 transmission housings (Material: EN-GJS-600).

Tap lifespan limited to 800 holes, requiring frequent tool changes.

- Solution:

- ① Implemented HiPIMS technology to deposit (Ti,Al,Si)N coating.

- ② Optimized thread lead angle (cutting force reduced by 30%).

- ③ Customized passivation treatment.

- Results:

- ✔ Tap lifespan increased to 3,200 holes.

- ✔ Passed VW's VDA6.3 process audit.

- ✔ Secured a 5-year framework agreement.

5.2 North American Medical Device Order Success

- Customer Requirements:

Machining orthopedic titanium implants (Surface roughness Ra ≤0.4μm).

- Technical Breakthroughs:

- ✔ Developed nanolayered coating (HV3200, friction coefficient 0.18).

- ✔ Innovative cooling strategy (kept tool tip below 150°C).

- ✔ Integrated real-time coating monitoring system.

- Certification Achievements:

- ✔ FDA 510(k) approval.

- ✔ Compliant with ASTM F136 medical titanium standards.

- ✔ Accepted into Johnson & Johnson’s supplier network.

5.3 Aerospace Composite Layer Drilling Challenge

- Challenges:

- CFRP + Titanium alloy stacked material drilling:

- Burr formation in CFRP layer.

- Severe adhesion in titanium alloy layer.

- Customized Solution:

- Gradient Transition Coating:

- Base Layer: CrN (enhances adhesion).

- Middle Layer: TiAlN/WC-C (10 alternating layers).

- Top Layer: Si-DLC (lubrication & anti-adhesion).

- Breakthroughs:

- ✔ Hole wall quality met BAC5613 standards.

- ✔ Drill lifespan extended from 15 to 120 holes.

- ✔ Machining efficiency increased by 60%.

6. Frequently Asked Questions About Coatings

6.1 Cost Concerns

Q: How much more expensive are coated tools? Are they worth it?

| Cost Factor | Uncoated Drill | Coated Drill | Difference |

|---|

| Purchase Cost | $28 | $35 | +25% |

| Parts Machined per Tool | 1,200 | 4,500 | +275% |

| Tool Change Downtime Cost | $16 | $5 | -69% |

| Total Cost per 1,000 Parts | $36.7 | $13.3 | -64% |

|

6.2 How to Choose the Right Coating?

Decision Tree:

- Is the material hardness ≥35HRC?

- Yes → Choose AlTiN-based multilayer coating.

- No → Choose TiCN-based multilayer coating.

- Is the cutting speed >150m/min?

- Yes → Add thermal barrier layer (e.g., Y₂O₃ doping).

- No → Focus on wear-resistant layer design.

- Are cooling conditions limited?

- Yes → Include solid lubricant layer (WS₂/MoS₂).

- No → Optimize pure hard-layer combination.

7. Conclusion

From gradient transition designs to intelligent variable-layer coatings, multilayer coating technology builds a "molecular armor" on cutting tools, tailored for complex machining conditions. This innovation not only extends tool life by 3-5 times but also strengthens China's competitive edge against global manufacturing giants in high-end machining.

HSSE TAP WITH TIN COATING

HSSE TAP WITH TIN COATING SOLID CARBIDE DRILL BITS WITH TiAlN COATING

SOLID CARBIDE DRILL BITS WITH TiAlN COATING

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.