Advanced manufacturing process and customized application solution for spiral point taps

In the World of Precision Manufacturing, a Quality Spiral Point Tap is Like a Thinking "Precision Gear" — It Must Understand the Material's Temperament and Anticipate the Challenges of Processing.

As a manufacturer with 20 years of experience in the foreign trade cutting tool industry, we understand the core principles of custom-made tools: breakthrough material science as the foundation, and practical experience as the guide, ensuring that each tap becomes an "invisible guardian" of our customers' production lines.

The core characteristics of spiral point taps and precise adaptation to machining scenarios:

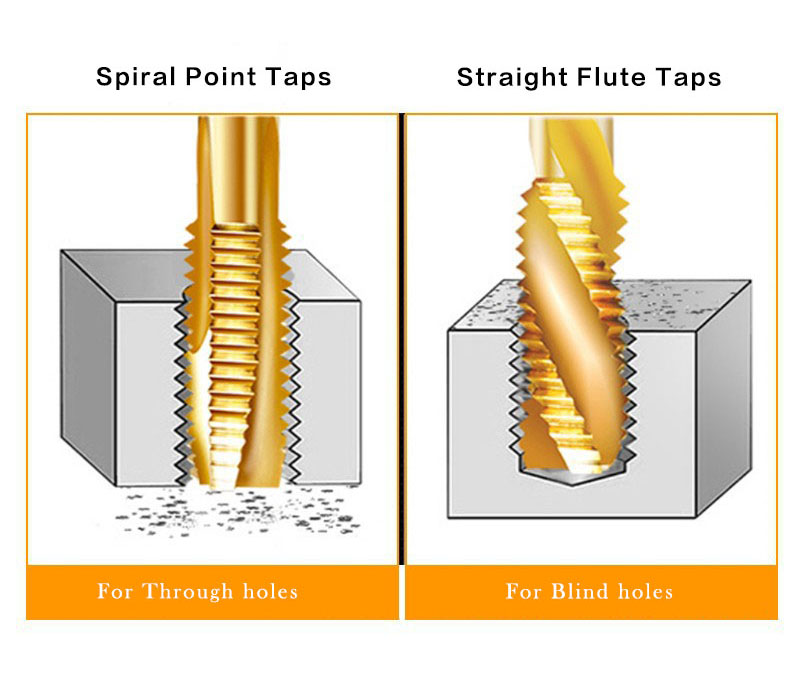

1. Essential characteristics: specially designed for through holes

- Chip oriented design: The geometric structure of Spiral Points forces chips to be discharged forward (along the bottom of the hole), making it mainly suitable for through-hole machining.

- Efficiency advantage: In through-hole scenarios, chips can fall directly without the need for reverse cutting, resulting in a processing efficiency improvement of over 50% compared to manual taps.

2. The double-edged sword of deep hole machining

- Applicable scenarios:

- Shallow through-hole (hole depth ≤ 3 times diameter): performs the best, with smooth chip cutting and no residue.

- Deep hole through hole (hole depth>5 times diameter): High pressure cooling system is required, otherwise long chips may entangle.

3. Taboo Scene:

- Blind hole processing: The spiral point structure cannot reverse chip discharge, and chip accumulation can easily lead to tool breakage (in this case, a spiral groove tap should be used).

Material's "Transformers": Choosing the Right Material = Half the Battle Won

1. The "Brotherly Duel" of HSS and HSSE

- Traditional HSS (High-Speed Steel):

- Suitable scenarios: General carbon steel, cast iron machining

- Economic advantage: 35% cost reduction for small batch orders

- Upgraded HSSE (Cobalt High-Speed Steel):

- High-temperature red hardness: 50% increase in hardness retention at 600°C

- Practical case: Machining 316 stainless steel screw holes, with a lifespan 3 times that of regular taps

2. The "Ultimate Challenge" of Carbide

- Micro Thread Expert:

- Can process M1.2 threads (about the thickness of a human hair)

- Patented cutting edge design: 0.02mm radius transition (compared under a microscope)

- Deep Hole Champion:

- Successful case: 12x diameter deep hole machining (total length 96mm)

- Anti-fracture design: Gradually thickened neck diameter (70% reduction in stress concentration)

The Spiral Angle's "Intelligent Navigation System"

1. The "Personality Test" Database for Metals

- Aluminum alloy's "sticky" nature → 25° spiral angle + polished groove wall design (friction coefficient reduced to 0.12)

- Stainless steel's "stubborn" essence → 12° spiral angle + negative rake edge (18% reduction in peak cutting force)

- Titanium alloy's "sensitive constitution" → 18° gradient spiral angle (0.7° change per mm)

2. Angle Dynamic Matching Technology

| Material Type | Recommended Angle | Special Treatment | Suitable Scenarios |

|---|

| Low carbon steel | 15° | Conventional polishing | General mechanical parts |

| Nickel-based alloys | 8° | Edge chamfer + micro-coating | Aircraft engine components |

| Ductile cast iron | 20° | Reinforced chip removal grooves | Automotive brake systems |

3. Special Mission for German Clients

- Challenge: Machining a 3mm diameter, 15mm deep hydraulic valve body thread

- Solution:

- Use a 12° starting angle with an intelligent variable angle design that increases by 0.3° per rotation

- Custom ultra-short shank structure (total length only 22mm)

- Results: ✔ Processing pass rate improved from 68% to 99% ✔ Single piece machining time reduced by 40%

The "Five-Layer Protective System" of Coating Technology

1. Protective Layer Structure Diagram

- [Substrate] → [Bonding Layer] → [Reinforcing Layer] → [Functional Layer] → [Smart Layer]

- Carbide → TiN → AlCrN → MoS₂ → Temperature-sensitive coating

- Smart Alert: When temperature exceeds 300°C, the coating turns red (like a "thermometer")

2. Extreme Environment Test Report

| Test Item | International Standard | Our Product Performance |

|---|

| High-temperature endurance | ISO 3685 | 750°C sustained machining for 1 hour without oxidation |

| Corrosion resistance | ASTM B117 | No rust in 5% salt spray environment for 200 hours |

| Adhesion resistance | DIN 50324 | Zero chip accumulation during aluminum alloy machining |

Chip Removal System's "Traffic Control Plan"

1. Three Core Designs

- Widened Lanes: Groove width increased by 20%, chip removal speed ↑35%

- Anti-clogging Curves: 60° inclined angle design to avoid iron filings accumulation

- Emergency Lane: Spare chip removal groove (depth increased by 0.1mm)

2. Three "Life-saving" Techniques for Deep Hole Machining

- Segmented Tapping Method: Withdraw every 3mm and clean chips every 0.5mm

- Coolant Formula: Special oil with extreme pressure additives

- Speed Control:

- Entry phase: 1500 rpm for fast entry

- Middle phase: 800 rpm for stable machining

- Exit phase: 200 rpm for fine finishing

Industry Challenges "Crack Files"

Scenario 1: Automotive Industry - Cast Iron Cylinder Body Tapping

- Pain Point: Frequent edge chipping

- Weaponry:

- Ultra-fine grain HSSE material (ASTM 12 grade)

- Composite alumina coating

- Reinforced neck radius design

Scenario 2: Medical Equipment Industry

- Headache: Micro-thread breakage in bone screws

- Innovative Solution:

- Medical-grade carbide material

- 0.005mm diameter jump control

- Outcome: Passed ISO 13485 medical device certification

Summary:

From the flexibility of titanium alloys to the crisis of deep hole tapping, from the rigor of German standards to the pragmatism of American standards, the custom spiral point tap manufacturing is a collaborative battle that crosses material science, fluid mechanics, and intelligent manufacturing. With millimeter-level precision control, intelligent coating systems, and a global service network, we have built a "continuous tapping defense line" for customers in 12 countries. When your production line faces stubborn machining problems, there is always a tap born to meet your needs.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.