In the world of precision machining, an ordinary flat end mill often serves as the invisible referee that determines production efficiency and product quality. When you’re troubled by issues like tool adhesion on stainless steel, burrs on aluminum alloys, or chipping on tool steel, the standardized design of general-purpose tools might be silently eroding your profits — and this is where the value of customized tooling comes into play.

Core Functions of a Flat End Mill:

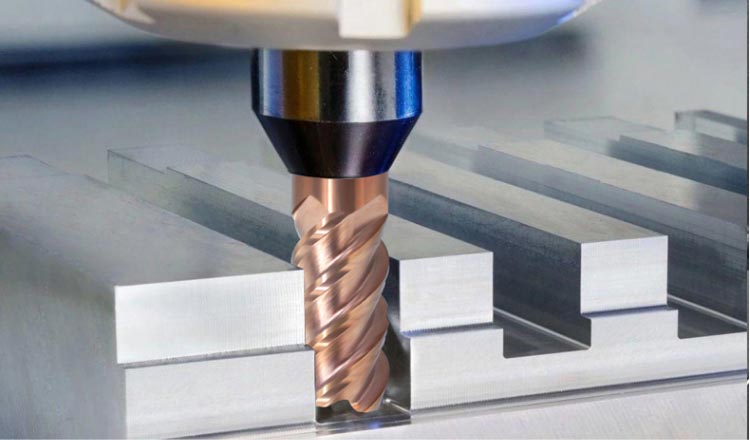

The flat end mill is the "precision engraving tool" in metalworking, designed specifically to create flat surfaces and right-angle structures. Through the rotating cutting edge, it performs:

- Flat Surface Machining — Efficiently mills large flat surfaces, 30% faster than ball end mills.

- Right-Angle Formation — Sculpting clean 90° steps on the edges of parts with an accuracy of ±0.02mm.

- Multi-material Compatibility — Customized edge profiles and coatings can solve issues like tool adhesion on stainless steel, burrs on aluminum alloys, and high-temperature resistance on titanium alloys.

Differentiated Value: Compared to general-purpose end mills, customized flat end mills are like tailor-made garments — by adjusting the number of flutes, helix angle, and coating combinations, tool life is increased by 2-5 times, making them especially suited for challenging applications like automotive part slots and precision slitting of 3C products.

The Scientific Formula Behind Customized Flat End Mills:

1. "Golden Ratio" of Material Selection:

- Upgraded High-Speed Steel (HSS):

- Cobalt Content Comparison: 8% Cobalt vs. 5% Cobalt in Stainless Steel Machining Tests

- Indicators:

Tool 5% Cobalt 8% Cobalt Tool Life 120 minutes 210 minutes Max Heat Resistance 550°C 620°C - Exclusive Heat Treatment Process: Triple tempering increases hardness uniformity by 90%.

2. "Transformation" of Carbide:

- Microscopic Structure Determines Fate:

- Standard Tools: Uneven grain size (1-3μm) → Prone to chipping.

- Customized Tools: Ultra-fine grain (0.5μm) with dual peak distribution → 3x longer tool life.

3. "Invisible Armor" of Coatings:

- Comparison of Four Coating Performances:

Coating Type Applicable Scenarios Heat Resistance Friction Coefficient TiN General Machining 600°C 0.6 TiAlN High-Temperature Alloys 900°C 0.45 AlCrN Dry Cutting 1000°C 0.35 Diamond Composite Materials 1200°C 0.1

The Devil in the Design Details:

1. "Mind Reading" Edge Design:

- Three Types of Edge Design:

- Straight Edge: Suitable for rough machining → High cutting force but prone to vibration.

- Wave Edge: Chip-breaking expert → Reduces chip length by 70%.

- Asymmetric Edge: Thin-wall material savior → Reduces deformation by 50%.

2. The Temperature Game of Helix Angles:

- Experimental Data Revealed:

Helix Angle Machining Temperature Surface Quality Applicable Scenario 30° 480°C Ra 1.6 Steel Roughing 45° 380°C Ra 0.8 Aluminum Precision Machining 60° 420°C Ra 1.2 Deep Slot Machining

3. "Highway" Design of Chip Removal Channels:

- Evolution of Slot Types:

- Straight Slot → V-slot → Parabolic Slot (Chip removal speed increased by 25%).

- Exclusive Lead Angle Technology: Lead angle variation of 0.5mm per turn reduces vibration by 40%.

Targeted Solutions for Industry Pain Points:

1. Automotive Manufacturing: Brake Disc Machining Challenges

- Traditional Issue: Cast iron dust accumulation → Stop every 50 parts for chip removal.

- Customized Solution:

- Deepen slots (20% deeper than standard).

- Surface sandblasting (reduces friction coefficient by 0.2).

- Effect Comparison:

| Indicator | Before | After |

|---|---|---|

| Continuous Machining Volume | 50 parts | 300 parts |

| Downtime | 2 hours | 0.5 hours |

2. 3C Electronics: Deformation of Mobile Phone Middle Frames

- Industry Standard: Processing 0.3mm thick aluminum alloy with pass rate <85%.

- Customized Solution:

- 2-flute asymmetric design (primary skew angle 88°+92°).

- 0.01mm edge passivation treatment.

- Results: Pass rate increased to 98%, tool cost reduced by 40%.

3. Mold Manufacturing: SKD61 Hardened Steel Nightmare

- Traditional Issue: Tool life <30 minutes, frequent tool changes.

- Innovative Solution:

- Substrate: Ultra-fine grain carbide (grain size 0.4μm).

- Coating: AlTiN+MoS₂ composite coating.

- Measured Data:

- Continuous Machining Time: From 28 minutes → 72 minutes.

- Surface Roughness: Ra 1.2 → Ra 0.6.

The Magic Formula for Cost Control:

1. Real Cost Calculator:

- Hidden Cost Revealed: Total Cost = (Tool Price ÷ Tool Life) + Tool Change Time Cost + Scrap Loss

- Example:

- General Tool: ¥200/unit × 3 units/day + Downtime Loss ¥500 = ¥1,100/day

- Customized Tool: ¥380/unit × 1 unit/day + Downtime Loss ¥100 = ¥480/day

2. Three Money-Saving Principles:

- Golden Ratio: Tool cost should account for 8%-12% of total machining costs for optimal balance.

- Life Warning: Replace tools when wear exceeds 0.3mm (includes comparison chart).

- Regeneration Plan: Recoating service for old tools (saves 60% on costs).

Application Examples:

Case 1: German Automotive Parts Factory

- Problem: Tool life for machining nodular cast iron is under 2 hours.

- Solution: K20 carbide + AlCrN coating + 30° helix angle.

- Result: Tool life increased to 6.5 hours, saving €52,000 annually.

Case 2: Vietnamese Electronics OEM Factory

- Challenge: 0.2mm ultra-thin aluminum part machining pass rate 65%.

- Solution: Double-flute asymmetric design + laser edge passivation.

- Result: Pass rate increased to 92%, daily production increased by 300 parts.

Interactive Toolbox:

1. Intelligent Selection Guide:

- Four-Step Quick Match:

- Select Material: [Aluminum Alloy / Stainless Steel / Titanium Alloy]

- Select Machining Type: [Roughing / Finishing]

- Select Machine Power: [<5kW / 5-10kW / >10kW]

- Get Recommended Solution: [Flute Count / Coating / Helix Angle Combination]

2. Online Self-Diagnostic System:

- Symptom Selection:

- Blue chips → Too high spindle speed.

- Machining surface with vibration marks → Tool overhang too long.

- Edge chipping → Incorrect rake angle.

- Four Diagnostic Checks:

- Look at Chips: Spiral chips ideal / Broken chips are dangerous.

- Listen to Sound: Buzzing sound normal / Screeching needs adjustment.

- Feel Temperature: Warm to the touch normal / Hot means stop machining.

- Check Wear: Edge reflection disappearing means tool replacement is due.

Conclusion:

From the microscopic revolution in material formulas to the precise tackling of industry pain points, customized flat end mills transform machining challenges into technological dividends. With a 20-year tool development database as our foundation, our "clinical diagnostic" custom service ensures every tool becomes an efficiency multiplier on your production line — after all, truly good tools never require compromise.

OEM Capability

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands. Categories

| HSS-PM Taps | HSSE-M42 Taps |

| HSSE / HSS Taps | Spiral Flute Taps |

| Straight Flute Taps | Spiral Point Taps |

| Multi-function Taps |

| Solid Carbide Drill Bits | Twist Drill Bits |

| Center Drill Bits | Indexable U Drills |

| Flat-end Milling Cutter | Ball Nose End Mills |