1. Definition and Role of Helix Angle

The helix angle refers to the angle formed between the cutting edge of the milling cutter and the axis of rotation. This angle is typically measured along the flute of the tool. The helix angle plays a significant role in the way the tool engages with the material during machining, influencing the cutting forces, chip removal efficiency, and overall stability of the cutting process. By controlling the angle, manufacturers can optimize the tool’s performance for specific applications.

The helix angle essentially determines how the tool enters the workpiece and removes material. A higher helix angle results in a smoother, more gradual entry into the material, while a lower angle causes a steeper, more abrupt engagement.

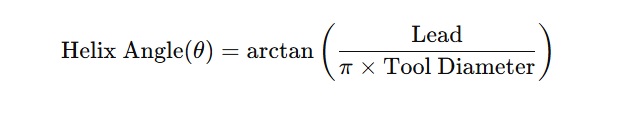

2. Calculation Methods and Measurement Techniques

The calculation of the helix angle typically depends on the geometry of the cutter and the cutting edges. It is calculated using the following formula:

Where:

Lead is the distance the cutting edge travels in one full rotation of the tool.

Tool Diameter is the diameter of the milling cutter.

In practice, measuring the helix angle requires precise instrumentation. Measurement techniques include the use of optical measurement systems or precision protractors in CNC machines. With advancements in digital tools, many modern milling machines come with built-in systems to accurately measure and adjust the helix angle for specific cutting conditions.

3. Impact of Helix Angle on Milling Performance

Cutting Forces and Cutting Temperature

The helix angle directly affects the cutting forces involved in the milling process. A larger helix angle distributes the cutting forces over a longer arc of the cutting edge, reducing peak forces. This leads to lower overall cutting forces, which helps to reduce tool wear and increase tool life. Additionally, with reduced cutting forces, the temperature at the cutting zone is also minimized, which can help to prolong both the tool and workpiece life.

A lower helix angle, in contrast, tends to concentrate the cutting force over a smaller area, generating higher cutting forces and temperatures, which may lead to increased tool wear or even thermal damage to the workpiece.

Cutting Stability and Vibration

Helix angles also have a significant impact on the stability of the cutting process. A higher helix angle promotes smoother material engagement and helps to minimize vibrations. This contributes to a more stable cutting action, reducing the likelihood of chatter and improving the quality of the finished surface.

Conversely, a lower helix angle can increase the likelihood of vibration, especially during high-speed cutting or when machining harder materials. Excessive vibrations lead to poor surface finish and can accelerate tool wear.

Surface Finish Quality

The smoothness of the entry and exit of the cutting edge during the machining process also affects the surface finish. A higher helix angle creates a more gradual and smooth entry, which results in better surface quality. This is particularly important in high-precision machining where surface finish is crucial.

On the other hand, a lower helix angle may result in a more abrupt material removal, which can cause rougher surfaces or even tool marks, especially in materials that are prone to deformation.

4. Selection and Optimization of Helix Angle

Advantages and Applications of High Helix Angles

High helix angles (typically above 45°) are used in applications requiring high cutting speeds and smoother finishes. The higher angle helps with better chip removal, making it ideal for machining soft and non-ferrous materials such as aluminum, brass, and plastics. It also minimizes the radial forces acting on the tool, which is beneficial for maintaining cutting stability in high-speed machining.

However, high helix angles are not suitable for heavy-duty or high-force cutting operations, as the tool strength may be compromised. In such cases, excessive wear or even tool failure could occur.

Advantages and Applications of Low Helix Angles

Low helix angles (typically 15°-25°) provide increased tool strength and are suitable for heavy-duty applications, including cutting hard materials such as steel, titanium, and cast iron. The lower angle enables more aggressive cutting and ensures that the tool maintains its integrity under high cutting forces.

While low helix angles help reduce the forces acting on the tool, they can also increase the cutting temperature and vibrations. Therefore, they are best used in environments where the cutting speed is lower, and strength is the primary concern.

5. Matching Helix Angle with Tool Materials

The selection of helix angle should be aligned with the material properties of both the cutting tool and the workpiece. For example, hard materials such as high-strength steels or titanium alloys benefit from lower helix angles as they require more force to cut, and a stronger tool is needed to handle these conditions.

For cutting softer materials like aluminum, higher helix angles are typically used. These materials allow for faster cutting speeds, and a high helix angle ensures efficient chip removal and a smooth finish. The tool material must also be matched appropriately—for harder materials, carbide or coated tools are preferred, while for softer materials, high-speed steel or cobalt alloys may be sufficient.

6. Innovations and Trends in Helix Angle Design

With the continuous advancements in milling tool technology, there has been a growing trend towards optimizing helix angles for specific applications. Modern tools often feature variable helix angles, where the angle changes along the length of the flute to suit different stages of the cutting process.

Furthermore, many cutting tool manufacturers are experimenting with advanced coating technologies to enhance the performance of tools with different helix angles. For example, tools with high helix angles may benefit from coatings that reduce friction and improve chip evacuation, while tools with low helix angles can be strengthened through coatings that improve wear resistance at high cutting forces.

Some tools also now feature a combination of different helix angles within the same tool to optimize performance for both roughing and finishing operations. This hybrid design allows the tool to perform efficiently across a range of cutting conditions.

Conclusion

The helix angle of a milling cutter is a critical parameter that influences the cutting forces, tool stability, surface finish, and overall performance of the tool. The proper selection and optimization of the helix angle based on material type, machining requirements, and tool strength can significantly enhance machining efficiency and product quality. With continued innovations in milling cutter design, future trends will likely focus on advanced geometries that provide even greater control over cutting processes, further improving manufacturing precision and efficiency.

OEM Capability

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands. Categories

| HSS-PM Taps | HSSE-M42 Taps |

| HSSE / HSS Taps | Spiral Flute Taps |

| Straight Flute Taps | Spiral Point Taps |

| Multi-function Taps |

| Solid Carbide Drill Bits | Twist Drill Bits |

| Center Drill Bits | Indexable U Drills |

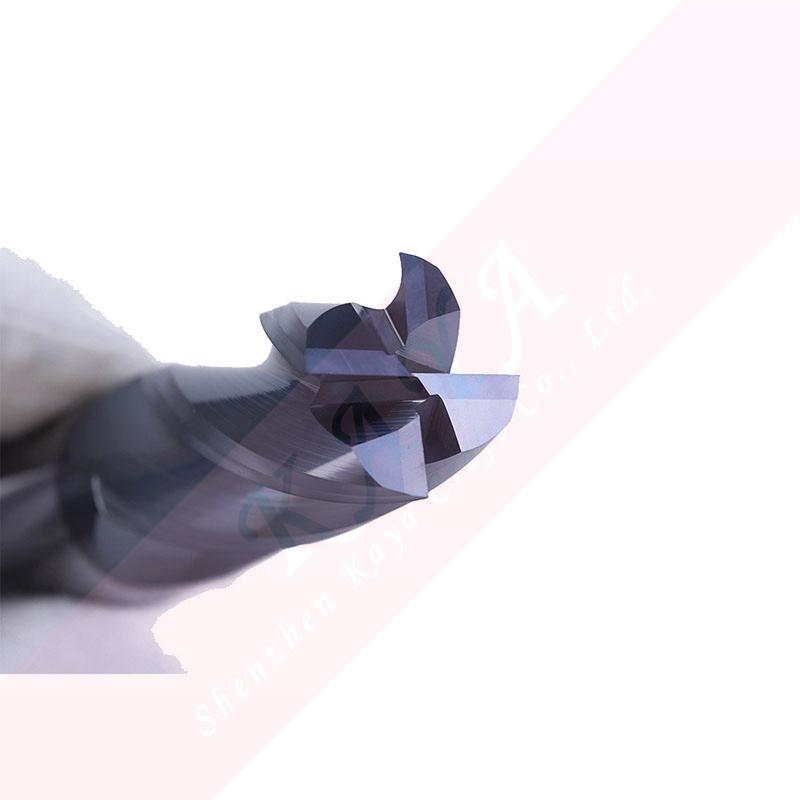

| Flat-end Milling Cutter | Ball Nose End Mills |